LEILI IMPLEMENTS THE MISSION OF "ADVANCING THE MOTOR INDUSTRY THROUGH EXCELLENCE AND LEADERSHIP"

As a provider of micro-motor system solutions, we leverage the Jiangsu Provincial Enterprise Technology Center, Engineering Technology Center, and National Industrial Information Management Standards to co-develop a product innovation system aligned with global customers.

R & D MANAGEMENT

Leili controls the entire process of product development through R&D management processes, project management processes, and target plan management.This increases efficiency, reduces risk, and ensures that products are delivered on time with the expected quality.

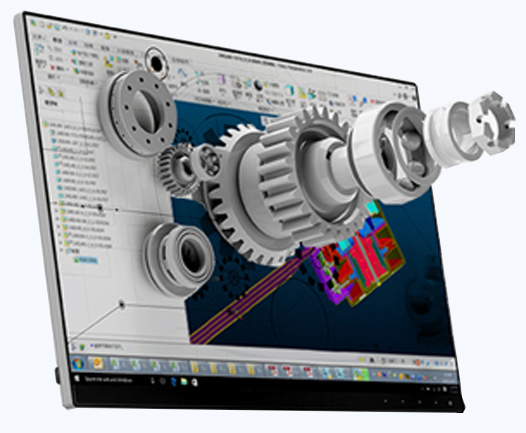

Project Management System

- In practical management, project management relies on the Product Lifecycle Management (PLM) system platform, integrating Creo and WindChill to enable 3D/2D linked design and modeling. The WindChill platform is further utilized for process information design and management.

Project Management Process

- Establish cooperation intention——Project approval——Manual sample stage——Mold design——Sample preparation and inspection——Small batch trial production——Batch delivery

R & D TECHNOLOGY

Developing high-quality products requires extensive data analysis and simulation testing.

Leili Motor leverages advanced analytical technology and industry expertise to ensure strict control over product customization and new product development.

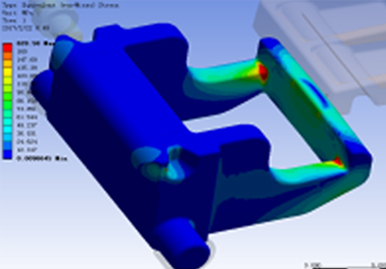

Structural Analysis

Use Ansys software to analyze and calculate product strength, plastic shell strength, deformation, etc., to provide reference for product optimization design.

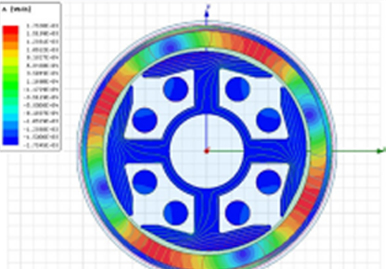

Electromagnetic Analysis

Use Maxwell software to simulate the motor magnetic circuit analysis, find out the best mechanism components and magnetic materials, and maximize the precision and ability of the motor.

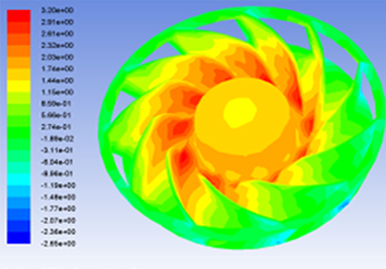

Fluid Analysis

In the development of parts such as valve pumps and fans that operate in liquid and air, it is necessary to use Fluent software to simulate and analyze flow pressure and air volume values.

Gear Calculation

Through KISS Soft, the gear design, gear transmission system design, shaft and bearing design are realized, and the strength analysis and optimization of the product are carried out.

University-industry Research Collaboration

The company consistently follows a path of collaborative innovation, seamlessly integrating internal and external technical resources.

Our company has established cooperative relations with Southeast University, Nanjing University of Aeronautics and Astronautics, Harbin Institute of Technology,

Huazhong University of Science and Technology, Changzhou University, Jiangsu University, Changzhou Institute of Technology, Jiangsu Institute of Technology,

Changzhou Mechanical and Electrical Vocational and Technical College and other universities.

R & D Platform

- Postdoctoral Research Workstation National

- Jiangsu Province's Graduate Workstation

- Research Center for Jiangsu Engineering Technology

- Jiangsu Province Enterprise Technology Center

- Jiangsu Provincial Engineering Research Center

- Changzhou Enterprise Technology Center

- Changzhou Engineering Technology Research Center

Government Program

- Key R&D project of Jiangsu Province

- Changzhou Science and Technology Achievement Transformation and Cultivation Project

- High-value Patent Cultivation Project in Jiangsu Province

- Changzhou High-value Patent Cultivation Demonstration Center Construction Plan Project

- Finish identifying new items and technology in Jiangsu Province

- Won the certification of the first (set) of major equipment in Suxichang

- Jiangsu Province industrial Internet development demonstration enterprise - benchmarking factory

ACHIEVEMENT TRANSFORMATION

Leili always insists on R&D and innovation, and has established long-term cooperative R&D relationships with research institutions and customers.

This has achieved good results for the company in terms of product patents and new product development.

Patent Achievements

159 Items

Invention Patent

128 Items

Appearance Patent

1154 Items

Utility Model

Project Result (2024 Jiangsu Leili Annual Report Data)

Home Appliance Field

In 2024, sales revenue increased by 12.75% year-on-year, with modular products being promoted and applied by small home appliance customers, resulting in a 45.07% year-on-year growth in revenue for these products.

Industry Field

In 2024, new products were launched for the industrial control field, including brushless motors, coreless motors, linear actuators, and high-efficiency industrial water pumps, achieving sales revenue of 419 million yuan, a 24% year-on-year increase.

New Energy Market

In 2024, products such as LiDAR motors, electric air-conditioning compressor motors and modules, and high-end precision die-cast parts achieved sales revenue of 612 million yuan, a 30.42% year-on-year growth, marking rapid expansion of the company’s products in the new energy vehicle sector.