Professionally Customize Automobile Motor

Recommended Supporting Suppliers for

Global First-tier OEMs

Industrial Product Supporting Capacity

Low Noise,High Quality,Safety, Low Energy Consumption

Industry Innovations

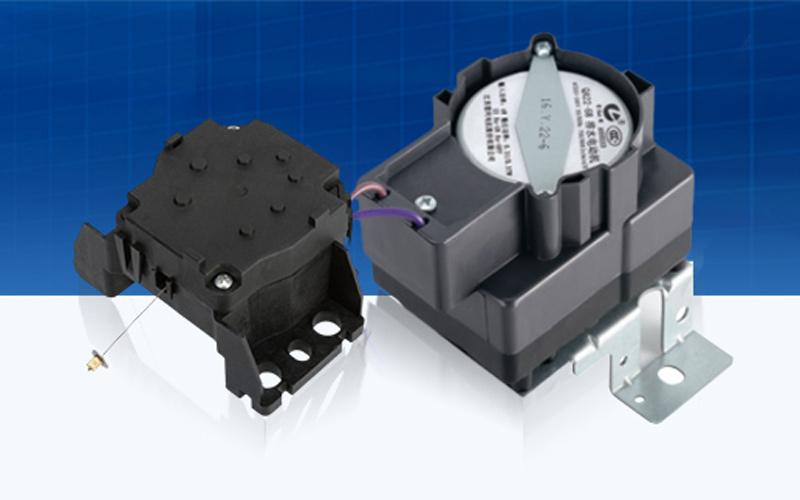

Dishwasher Dispenser Series

- Intelligent tips for a comfortable home life

- Reliable dispensing for the ultimate experience

- Highly adaptable to meet the diverse needs of users

- Modular design for easy operation

New Products for Automotive Air Conditioning Applications

Automotive Air Damper / Motorised Air Vent Actuator

- Miniaturised solutions, Smaller size, Meet the demand for lightweight automotive products

- Domestic chip, Stable supply, Maintain a certain price advantage

- Consistent size and performance, Can replace the imported product programme

Founded in 1993

Stock code 300660

Qualification

Professional customization

Annual production:200 million motors+

500+

World famous brand partner

Products and Applications

-

Home Appliance Market

Committed to providing innovative solutions for the global home appliance industry

- Leading brand in global air conditioning sweep motor market

- A global leader in washing machine drainage systems

- Global Refrigerator lce Water System Solution Provider

Home Appliance Market

Committed to providing innovative solutions for the global home appliance industry

- Customer Cases

- Specific Classfication

Air Conditioner

Air Conditioner Refrigerator

Refrigerator Washing Machine

Washing Machine Kitchen & Bathroom

Kitchen & Bathroom Small Home Appliances

Small Home Appliances

-

Auto Parts

Provide motor and mechatronic components for automobiles

- Product advantages of stepper motors for HUD

- Large-scale automotive water pump production capacity

- Automotive air conditioning system solution capabilities

Auto Parts

Provide motor and mechatronic components for automobiles

- Customer Cases

- Specific Classfication

Air Conditioning System

Air Conditioning System Thermal Management

Thermal Management Intelligent Driving

Intelligent Driving Intake & Exhaust System

Intake & Exhaust System Body Control

Body Control Braking System

Braking System

-

Industrial Control

Provide cost-effective motor and component products in the industrial field

- First-tier brand suppliers in the valve control market

- Domestic security monitoring head enterprise supplier

- Multiple series of products meet different application scenarios

Industrial Control

Provide cost-effective motor and component products in the industrial field

- Customer Cases

- Specific Classfication

Valve Control

Valve Control OA Finances

OA Finances Garden Tools

Garden Tools Industrial Equipment

Industrial Equipment Security Monitoring

Security Monitoring Robot

Robot

-

Sports Health

Provide high-quality motors for sports equipment and medical equipment industries

- High-end sports equipment main drive motor supplier

- First-tier brand suppliers in the medical device industry

- Ability to provide solutions such as smart furniture

Sports Health

Provide high-quality motors for sports equipment and medical equipment industries

- Customer Cases

- Specific Classfication

Sports Equipment

Sports Equipment Medical Instruments

Medical Instruments Game Entertainment

Game Entertainment Smart Home

Smart Home

Outer Diameter 20-50mm

Outer Diameter 6.5-60mm

Outer Diameter 35-60mm

Motors for Valve Control

Full Range of Brushless Types

Various Options Available

DC/AC Programme

Washing Machine Drain Pumps

Automotive Heat Management Pumps

Motors for Valve Control

New Products

- The industrial motor on the market is mainly AC high energy consumption, and the application of permanent magnet motor is less.

Rare Earth Removal Efficient

Permanent Magnet Synchronous Motor

More efficient and energy-saving than same-priced asynchronous motor.

Trending for Industrial Motor Development

- High efficiency, energy saving and green development

- Intelligent and integration

Self-developed Stator Soft Magnetic Material

- Strong plasticity, simple manufacturing process

- Energy saving, environmental protection, high strength

Self-developed Magnetic Rotor Material

- High dimensional stability

- Double permeability design, improve the motor full frequency high efficiency band

Integrated Design

- Small size, light weight

- Intelligent, low noise

- Domestic dishwasher penetration rate is low, the market demand has continued to increase in recent years, the market outlook is large.

Industry Innovative

Intelligent Dishwasher Dispenser

Multiple options for different types of detergents.

Dishwasher Development Trend

- High-end functional requirements

- Wider market prospects for embedded / single-use

- Dishwasher detergents towards integration and liquidisation

Highly Adaptable

- Four options to choose from

- Meets most of the dishwasher detergent dispensing needs on the market

Reliable Detergent Dispensing

- Reliable, active pushing out of the dishwasher block

- Liquid filling pump with good liquid viscosity adaptability

Modular Design

- Modular design, simple structure

- Plug-in installation of the dosing pump

- Increasing demand for automotive comfort, automotive air conditioning market trends towards electrification and intelligence.

Automotive Air Damper / Motorised Air Vent Actuator

Miniaturised solutions for lightweight requirements.

Automotive Air Conditioning Air Vents Market Trends

- Automotive air conditioning air vents electrification, intelligence

- Large air outlet area, wide-angle wind sweeping

- Require high efficiency and good stability of air vents

Product Lightweighting

- Miniaturised solutions with smaller dimensions

- Meet the demand for lightweight automotive products

Stable Supply

- Domestic chip, can provide stable supply

- Maintain a certain price advantage

Substitute for Imported Products

- Maintain the same size and performance

- There can be a substitute for imported products programme

Client Cooperation

Providing you with a full range of CUSTOMISED SERVICES

Relying on the application advantages and customer base in the drainage system of washing machines, Leili continues to meet the needs of new projects of customers and provide customized solutions for the functional requirements of high-end washing machines. After years of research and development, the automatic feeding system for washing machines has been mass-produced by customers such as Little Swan and Whirlpool.

The application of Leili motor in refrigerator products is mainly synchronous motor. In recent years, the customer’s demand for refrigerator ice-making function, Leili motor and the customer close communication, collaborative research and development of refrigerator ice and water system components, for the customer to produce high-end refrigerator to provide assistance. At present, the refrigerator component products have been developed in series for different application scenarios of different customers such as Whirlpool, Midea and GE.

News Center

LEILI is excited to participate in the upcoming 137th Canton Fair, scheduled from April 15th to April 19th at the Canton Fair Complex, No.382, Yuejiang Zhong Road, Guangzhou. As a global leader in motion control and motor solutions, LEILI is excited to meet customers, partners, and visitors from around the world during this premier international trade event.

This spring session of the Canton Fair, known as China’s largest and most comprehensive trade fair, presents an invaluable opportunity for industry professionals to explore the latest trends, forge new connections, and discover cutting-edge products. At LEILI, we are proud to be part of this dynamic platform once again.

Visit LEILI at Booth No. 19.2E35-36, 19.2F13-14

We warmly welcome all attendees to visit us at our booth No. 19.2E35-36 and 19.2F13-14, where we will showcase our full portfolio of innovative motor products and intelligent drive systems. From precision micro motors to integrated motion control solutions, LEILI’s products are widely applied in smart home appliances, medical equipment, industrial automation, and automotive systems.

Visitors will have the chance to:

- Examine the introduction of new products with cutting-edge features and increased effectiveness.

- Experience live demonstrations of our motor solutions in action

- Engage with our professional team to discuss custom solutions for your application needs

- Discover LEILI’s latest R&D advancements in brushless motors, stepper motors, servo systems, and more

With over two decades of expertise and a strong commitment to innovation, LEILI continues to lead the way in delivering reliable, energy-efficient, and intelligent motor solutions to clients around the globe.

What to Expect at LEILI’s Booth

Our booth will highlight LEILI’s core technologies and product advantages. You’ll see:

- High-performance BLDC motors designed for smooth operation and high torque output

- Stepper motors and gear motors developed for precise positioning and quiet operation

- Advanced servo drive systems offering superior control for industrial automation

- Customized motor assemblies tailored to meet specific customer requirements

Our engineering and sales teams will be on-site, ready to provide in-depth technical support and one-on-one consultation. Whether you’re seeking a standard model or a fully customized solution, LEILI offers the flexibility and expertise to support your unique project.

Let’s Connect and Innovate Together

The Canton Fair is more than an exhibition — it’s a global meeting point for ideas, technology, and partnerships. At LEILI, we believe in the power of collaboration to create smarter and more sustainable motion solutions. We look forward to sharing our vision and learning from your insights.

Mark your calendar:

📅 Date: April 15–19, 2025

📍 Venue: Canton Fair Complex, No.382 Yuejiang Zhong Road, Guangzhou

🧭 Booth: 19.2E35-36, 19.2F13-14

Welcome to our booth — let’s shape the future of motion together!

A brushless direct current (DC) motor, also known as a synchronous electric motor, is driven by DC electricity instead of a mechanical commutation system. Brushless DC motors have high efficiency and reliability, help lower acoustic noise, and offer dynamic response, high speed range, and long durability, which are among the key features expected to leverage the brushless DC motor market growth.

Request For Sample Copy of this Research Report:https://www.coherentmarketinsights.com/insight/request-sample/1438

The higher efficiency of brushless DC motors in comparison with other induction or magnetic motors is driving the growth of the brushless DC motors market. Brushless DC motors are more efficient than their brushed DC counterparts, as it is associated with lower mechanical wear outs, thus lowering maintenance costs.

Brushless motor operates at low temperatures, require minimum maintenance, are thermally resistant, and remove any threat of sparks. This, in turn, has increased the demand for brushless motors over other types. Integration of sensor-less controls in brushless DC motors helps boost the durability and reliability of the product, in turn decreases the number of mechanical misalignment and electrical connections and reduces the weight and size of the product. The demand for the sensor-less controls from the industrial machinery has increased considerably due to its low cost and robust motor drives.

Among end users, the industrial automation equipment segment held the largest market share in the brushless DC motors market due to the growing demand for hybrid and electric cars. According to the International Energy Agency, in 2016, electric car sales were over 750 thousand worldwide. The consumer goods segment is rapidly growing due to increasing demand for heating, ventilation, and air conditioning (HVAC) technology, which in turn is increasing the demand for brushless DC motors.

Asia Pacific held the large brushless DC motors market share due to the rising production of electric cars and increasing demand for consumer electronics. According to the International Energy Agency, in 2016, China held the largest market share in the electric cars market, accounting for over 40% of the global electric cars sold.

The market in North America is expected to witness the fastest growth due to the growing demand for extremely sophisticated medical devices. For example, the development of positive airway pressure (PAP) breathing apparatus for the treatment of sleep apnea. This device, which helps patients in breathing also employs a brushless DC motor to power the blower fan.

Key players operating in the brushless DC motors market include Johnson Electric, Ametek, MinebeaMitsumi Inc., Allied Motion Technologies Inc., Maxon Motor AG, Emerson Electric Corporation, ABB, Nidec Corporation, and ARC Systems.

For More Information: https://www.coherentmarketinsights.com/ongoing-insight/brushless-dc-motors-market-1438

Another year of glorious blossoms in spring and solid fruits in autumn, let us forge ahead and open a new chapter. On November 26, 2024, the signing ceremony of the cooperation agreement “Research and Development of Six-Phase Brushless Motor and Controller with Torque Feedback” between Changzhou Leili Motor Technology Co., Ltd., a subsidiary of Jiangsu Leili, and Southeast University was successfully held at Motor Technology. Liu Xiaoyu, chairman of the Science and Technology Association of Changzhou Xinbei District and member of the Party Group of the District Science and Technology Office; Huang Yunkai, member of the Party Committee and deputy dean of the College of Electrical Engineering of Southeast University; and Jiang Zheng, deputy director of Longhutang Street of the district, attended the event.

At the ceremony, Su Da, Director General of Engine Technology, welcomed and thanked the visitors and stated that the signing of this industry-university research cooperation agreement marks a milestone in the more than 10 years of cooperation between the two sides, which will further boost cooperation. Engine Technology will continue to adhere to the principles of open cooperation and mutual benefit, and will explore new solutions and models with Southeast University in talent development, scientific research, and the transformation of achievements, jointly exploring the development of cutting-edge fields.

Huang Yunkai, Vice President of the College of Electrical Engineering at Southeast University, introduced the cooperation project and the university’s current research direction and held in-depth discussions with Mr. Su and the technical team. Liu Xiaoyu, President of the District Science and Technology Association, praised the cooperation between the College of Electrical Engineering and Southeast University. He noted that the government will provide policy support and guidance, and expressed his hope that the three parties—the college, the district, and the enterprise—will cooperate and promote technological innovation to a higher level. After the ceremony, Mr. Su led a delegation of guests to visit the company’s exhibition hall, introducing the company’s mature and outstanding products one by one and sharing future development plans.

We firmly believe that through close collaboration and collaborative efforts between schools and businesses, they can quickly meet the operational needs of intelligent driving in the new energy market and promote the development of new-level productivity. At the same time, both sides will actively explore new models of deep integration between industry, academia, and research, seeking to share resources and gain complementary advantages by cultivating high-quality innovative talent and creating high-level scientific research platforms, thereby boosting the competitiveness and social influence of enterprises.

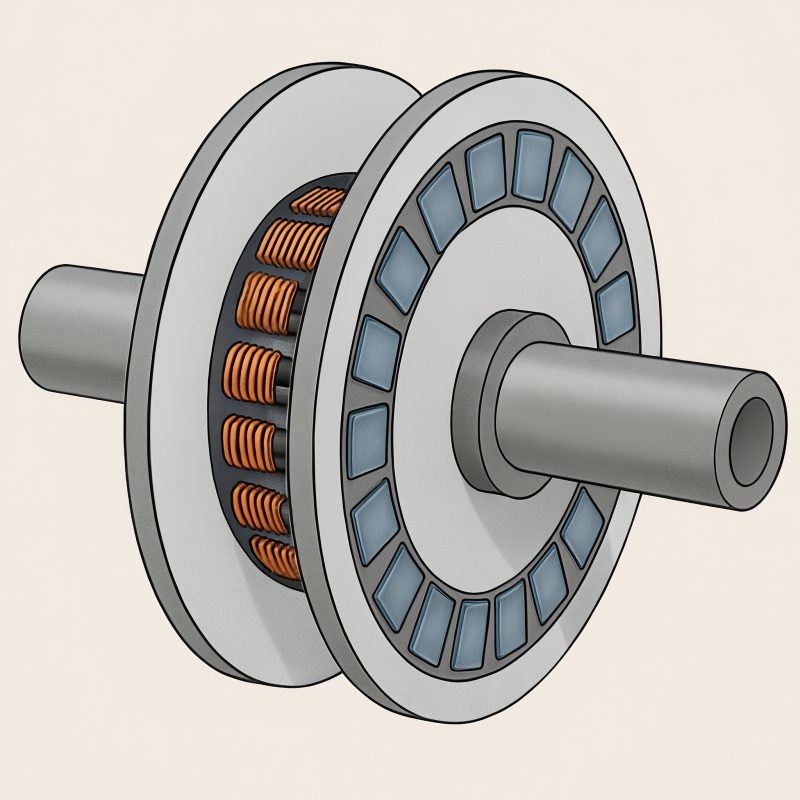

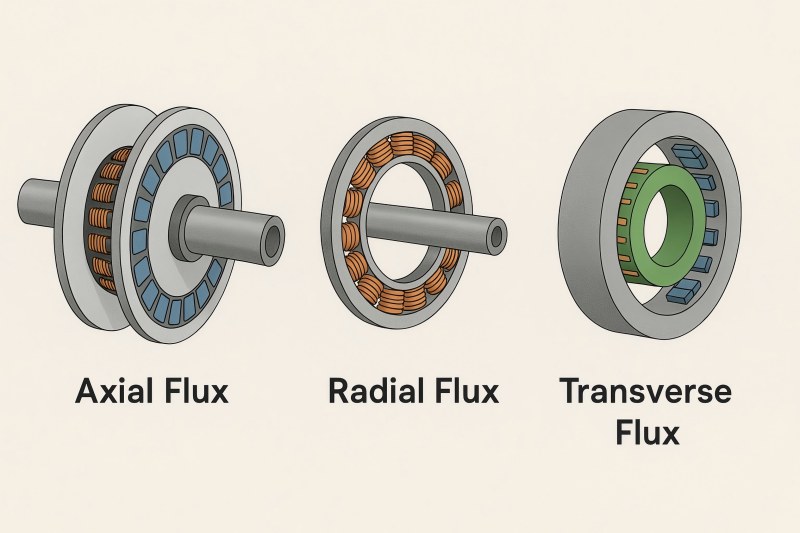

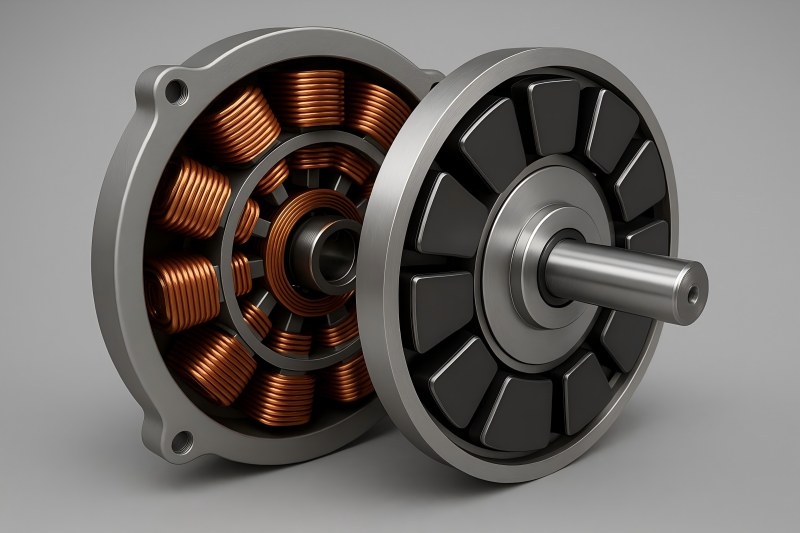

Axial flux motors (AFMs) have surged from research labs into real products—from robotics and e-mobility to aerospace and distributed generation. Their disc-like geometry packs high torque in a short axial length, enabling thin, pancake-style machines that fit where traditional cylindrical (“radial flux”) motors struggle.

What is an Axial Flux Motor?

In an axial flux machine, magnetic flux travels parallel to the shaft (axially) across a flat air gap between a rotor disc with permanent magnets (or a wound field) and a flat stator disc with windings. By contrast, radial flux machines guide flux radially, across a cylindrical air gap between an inner rotor and outer stator. The axial configuration creates a large effective lever arm (mean radius), so for a given air-gap shear stress the torque scales roughly with the cube of radius and only linearly with axial length. That’s why AFMs tend to offer excellent torque density for a given mass and especially for limited axial space.

Common AFM topologies

- Single-stator, single-rotor (SS-SR): Simplest build; unbalanced axial magnetic forces must be handled structurally.

- Double-rotor, single-stator (DR-SS): Rotors on both sides of one stator balance axial forces and double the active area for the same diameter.

- Double-stator, single-rotor (DS-SR): A central rotor sandwiched by two stators; also balances axial forces and doubles active copper.

- Yokeless and segmented armature (YASA-type): Segmented tooth modules without a continuous back iron reduce iron mass and eddy losses, thereby improving torque density.

- Coreless (air-core) stator: Eliminates iron teeth to remove cogging and iron losses virtually; great for smoothness and partial-load efficiency, but lower flux density and higher copper mass.

- PCB stator (very low power): Spiral copper traces on FR-4 or polyimide; exceptional thinness and precision for fans/micro-drives at low torque.

Why Choose (or Not Choose) an AFM?

Strengths

- High torque density at modest diameter; thin “pancake” packaging with short axial length.

- Low cogging potential (especially with coreless or yokeless designs), yielding smooth motion and low acoustic noise.

- Scalability in disc area: Large-diameter, low-speed direct-drive generators/motors (e.g., wind, flywheels, test benches).

- Short end-turns with concentrated windings (in many AFMs) reduce copper loss.

Limitations

- Tighter air-gap control required: the flat faces must remain parallel under load and temperature.

- Thermal paths can be tricky: Large, thin discs need thoughtful heat extraction to avoid hot spots.

- Higher pole counts lead to higher electrical frequency at a given rpm (impacts inverter and losses).

- Manufacturing complexity for segmented stators, magnet fixtures, and rotor banding—especially at high rpm.

Typical Performance Ranges (Indicative)

Real performance depends on materials, cooling, control, duty cycle, and safety margins. The following ranges are conservative but useful for initial screening:

- Peak air-gap flux density (NdFeB): 0.6–0.9 T (teethed), 0.3–0.5 T (coreless)

- Specific electric loading (A, RMS): 20–60 kA/m (air-cooled), up to ~80 kA/m (aggressive liquid cooling)

- Continuous torque density: ~8–25 N·m/kg (well-cooled designs); peak can exceed 30–60 N·m/kg for short bursts

- Continuous power density: ~1–3 kW/kg; peak ~2–6 kW/kg (brief)

- Peak efficiency: 92–97% (properly optimized)

- Air gap: 0.3–1.5 mm typical (smaller at lower diameter/lower runout)

- Pole pairs: 6–40 (higher for large diameters/low speed)

These are not hard limits; specialized designs, advanced cooling (spray/oil jet, cold plates), and premium magnets can exceed them.

Losses and Efficiency

- Copper (I²R) losses: Dominant at high torque. Reduce via larger conductor cross-section, lower winding temperature, and higher fill factor (35–55% is typical with round or rectangular wire).

- Iron losses (hysteresis + eddy): Significant in teethed stators; reduce via thin laminations (0.1–0.35 mm), low-loss grades, or Soft Magnetic Composites (SMC) in 3D flux regions.

- Proximity & skin effect: Grow with electrical frequency and conductor geometry; mitigated by litz wire (low-power) or shaped bar conductors (higher power).

- Mechanical & windage: Rotating discs can incur windage; shrouding and smooth surfaces help.

- Inverter (switching + conduction) losses: Rise with electrical frequency (which rises with pole count at a given rpm). Correct device choice (SiC/MOSFET/IGBT), optimal PWM, and appropriate switching frequency are key.

Thermal Management

AFMs are thin and wide, so heat must be moved radially and axially out of copper and iron:

Conduction paths: From teeth/tooth-coils to back-iron to housing; or directly from slot/coil to a liquid-cooled plate.

Cooling options:

- Air convection over stator faces, with finned housings

- Liquid cold plates behind the stator

- Spray/oil-jet cooling directly on windings (advanced)

Heat flux ballparks: ~5–15 kW/m² (forced air), ~30–100 kW/m² (liquid plates), and higher for direct oil impingement with careful insulation.

Materials and Manufacturing

Magnets

- NdFeB (N42–N52, H/EH grades): Highest energy density; watch max temperature (80–180 °C depending on grade).

- SmCo: Lower remanence but far better thermal stability (200–300 °C); excellent for high-temp or demag-robust designs.

- Ferrite: Cheap and stable but low energy density; viable with flux concentration structures.

Stator iron

Electrical steel laminations (0.1–0.35 mm) for teethed stators; SMC for complex 3D flux; or none for coreless.

Windings

Round-wire coils, rectangular “hairpin-style” (less common in AFM but possible), or litz for high frequency/small machines.

PCB windings for micro-AFMs at low torque.

Rotor integrity

Magnets bonded to a steel or composite carrier; at higher rpm use non-magnetic banding (e.g., carbon fiber sleeves) to contain hoop stress and prevent magnet throw.

Tolerances

Flatness and parallelism matter. Air-gap uniformity within tens of microns improves efficiency and lowers acoustic noise.

Dynamic balance typically to ISO 21940 G2.5 (or better) for quiet operation.

AFM vs Radial Flux vs Transverse Flux

Below is a practical comparison. Values are indicative—not absolutes—and assume competent cooling and modern materials.

| Attribute | Axial Flux (AFM) | Radial Flux (RFM) | Transverse Flux (TFM) |

| Packaging | Thin “pancake”, short axial length | Longer axial length, smaller diameter | Bulky, complex magnetic paths |

| Continuous torque density | High (8–25 N·m/kg, higher with liquid cooling) | Moderate–High (6–20 N·m/kg) | Potentially very high but hard to realize |

| Power density | 1–3 kW/kg (cont.), 2–6 kW/kg (peak) | 1–2.5 kW/kg (cont.), up to ~4 kW/kg (peak) | High potential; complex manufacturing |

| Pole count (typ.) | Medium–High (6–40 pairs) | Low–Medium (3–12 pairs) | High |

| Electrical frequency at given rpm | Higher (due to more poles) | Lower | Higher |

| Cogging & ripple | Very low with coreless/yokeless | Low–moderate (mitigation required) | Depends on design; often challenging |

| Cooling | Needs careful planar heat paths | Well-understood radial paths | Complex |

| Manufacturing difficulty | Moderate–High (discs, banding, precision) | Mature supply chains | High (3D flux paths) |

| Best fit | High torque in tight axial space; direct drive | General-purpose; wide speed range | Niche high-torque, low-speed applications |

Quick Sizing by Shear Stress

A fast way to estimate AFM diameter is to assume a tangential air-gap shear stress and a ratio between inner and outer radii. For many AFMs, the continuous shear stress falls around 20–40 kPa with good air- or liquid-cooling (peaks can be higher briefly).

| Rated Power | Speed (rpm) | Torque (N·m) | Suggested ror_o (m) | Outer Ø (m) | Electrical Frequency* (Hz) |

| 5 kW | 1500 | 31.83 | 0.0833 | 0.167 | 500 |

| 10 kW | 3000 | 31.83 | 0.0833 | 0.167 | 1000 |

| 25 kW | 3000 | 79.58 | 0.1131 | 0.226 | 1000 |

| 50 kW | 3000 | 159.15 | 0.1425 | 0.285 | 1000 |

| 100 kW | 3000 | 318.31 | 0.1796 | 0.360 | 1000 |

| 25 kW | 1000 | 238.73 | 0.1631 | 0.326 | 333 |

| 50 kW | 1000 | 477.46 | 0.2056 | 0.411 | 333 |

| 100 kW | 1000 | 954.93 | 0.2590 | 0.518 | 333 |

Key Design Parameters and Practical Ranges

Air gap

- 0.3–1.5 mm is common. Larger diameters and higher speeds push you to larger gaps for safety; precision machining and stiff structures let you shrink it.

Magnet thickness & pattern

- 2–6% of outer diameter as a loose starting point for medium sizes.

- Halbach arrays boost air-gap flux and reduce back-iron needs but add complexity.

Slot/pole combinations

- Fractional-slot concentrated windings (e.g., 12-slot/10-pole, 24-slot/22-pole, etc.) reduce end-turn copper and cogging.

- Ensure least common multiple (LCM) of slots and poles supports balanced three-phase windings and acceptable space harmonics.

Current density (in copper)

- 3–6 A/mm² RMS for air-cooled continuous, up to ~10 A/mm² (or more) with top-tier liquid cooling.

- Watch hot-spot temperature at tooth roots and the middle of thick coils.

Mechanical integrity

- Verify rotor hoop stress at max speed (typ. test at 120–150% of rated).

- Use non-magnetic sleeves (carbon fiber) to retain magnets at high rpm.

NVH (noise, vibration, harshness)

- Reduce cogging via magnet skew, tooth chamfering, fractional slot/pole, and coreless designs.

- Balance statically and dynamically; aim for low radial/axial pulsations in electromagnetic forces.

Materials Selection

| Component | Option | Pros | Cons | Notes |

| Magnets | NdFeB (N42–N52, H/EH) | Highest energy density; compact | Demagnetization at high temp; price volatility | Verify B HmaxB\!H_{max}BHmax, HciH_{ci}Hci; pick grade for thermal headroom |

| SmCo | High temp stability; corrosion-resistant | Lower energy; cost | Great for >180 °C operation | |

| Ferrite | Cheap; stable | Large volume; low flux | Works with flux concentration topologies | |

| Stator | Laminated steel (0.1–0.35 mm) | Mature; good loss control | 2D lamination constraints | Pick low-loss grades for high frequency |

| SMC | 3D flux capability | Lower permeability; higher loss at low freq | Useful for segmented teeth/yokeless | |

| Coreless (no iron) | Near-zero cogging; low iron loss | Lower flux density; more copper | Excellent smoothness/precision | |

| Windings | Round wire | Flexible, easy | Lower fill than rectangular | Good for prototypes and many series builds |

| Rectangular/bar | Higher fill, better thermal contact | Tighter bends; process control | Consider for >10 kW machines | |

| Litz | Reduces skin/proximity losses | Costly; sizing complexity | Suits high freq, small machines |

Control and Inverter Considerations

Field-Oriented Control (FOC) with sinusoidal commutation is standard. Concentrated windings introduce space harmonics; good current controllers and filtering mitigate torque ripple.

Electrical frequency rises with pole count: fe=p⋅rpm/6 High fe increases core/switching losses; SiC MOSFET inverters help at higher voltages/frequencies.

Back-EMF shape (trapezoidal vs sinusoidal) depends on slot/pole and magnet shaping; sinusoidal reduces ripple and acoustic noise.

Sensoring: Encoders or resolvers for high dynamic performance; sensorless FOC possible but harder at low speed.

DC link & filtering: With high pole counts, ensure adequate DC-link capacitance and consider dv/dt on windings (partial discharge risk at high voltage).

Application Snapshots

- E-Mobility (e-motorcycles, light EVs, AGVs): Thin form factor frees up packaging; high torque at wheel speed; watch thermal management in sealed housings.

- Aerospace/eVTOL: High torque density and smoothness are attractive; materials must meet stringent temperature and reliability requirements; SmCo may be favored.

- Robotics/Co-bots: Coreless AFMs excel where ultra-smooth, low-cogging torque and back-drivability matter.

- Wind & direct-drive generators: Very large-diameter axial flux alternators at low rpm; ferrite or NdFeB with flux concentration to manage cost.

- Industrial spindles & test rigs: Thin profile allows direct-drive torque at modest speed without gearboxes, reducing backlash and maintenance.

Integration Tips (What Often Gets Missed)

- Axial force balance: Favor DR-SS or DS-SR to cancel magnetic attraction; it relaxes bearing selection and housing stiffness.

- Runout and flatness: Measure it hot. Composite rotors and aluminum housings expand differently; keep the gap safe at max temperature and max rpm.

- EMC & cabling: High pole counts/electrical frequencies raise dv/dt stress; choose proper cable shielding and winding insulation class.

- Magnet retention & safety: Design for overspeed and thermal excursions; potting and sleeves must block magnet lift-off.

- Serviceability: Segmented stator teeth and modular rotors reduce downtime for coil/PM replacement.

- Thermal sensors: Bury RTDs/NTCs near tooth roots and middle of dense coils to catch hot spots early.

- Cost realism: Premium magnets and tight machining tolerances dominate BOM; early DFM with your supplier avoids last-minute cost creep.

Axial flux motors win when the envelope demands high torque in minimal axial length and when smoothness, compactness, and modularity matter. To realize that promise, you must nail air-gap control, thermal paths, and inverter matching, and select materials that fit your temperature and cost realities. Use the shear-stress sizing shortcut to get in the right diameter ballpark, pick a topology (DR-SS and DS-SR are workhorses), and iterate with your supplier on cooling and manufacturability. With sound engineering, AFMs deliver standout torque density and refined operation across e-mobility, aerospace, robotics, and direct-drive generation.

The electrification of transportation, robotics, and industrial systems has accelerated the development of compact, high-efficiency electric motors. Among the most innovative designs is the axial flux motor (AFM), known for its flat geometry, high torque density, and space-saving benefits compared to traditional radial flux machines.

As industries search for ways to maximize efficiency, two integration pathways have gained prominence: combining axial flux motors with gearboxes for torque multiplication, and deploying them in direct-drive systems where mechanical transmission is eliminated.

Understanding Axial Flux Motors

Geometry and Operation

Unlike radial flux motors, where the magnetic flux flows radially through the stator and rotor, axial flux motors have magnetic flux traveling parallel to the shaft. This flat, pancake-like design yields:

- High torque density – more torque per unit volume.

- Compact axial length – ideal for space-constrained applications.

- Short end windings – improved copper utilization and reduced resistive losses.

Key Applications

Axial flux motors are increasingly applied in:

- Electric vehicles (EVs and e-bikes).

- Aerospace propulsion systems.

- Industrial robotics.

- Renewable energy generators (e.g., wind turbines).

Integration Pathways: Gearbox vs. Direct-Drive

Two main methods exist for integrating axial flux motors into mechanical systems:

- With Gearboxes – AFMs provide speed, while the gearbox multiplies torque and adapts output to the load.

- Direct-Drive Systems – AFMs directly couple to the load, eliminating intermediate gears.

Every method offers unique benefits and corresponding compromises.

Axial Flux Motors with Gearboxes

Why Pair with Gearboxes?

Despite high torque density, axial flux motors often operate at higher speeds for efficiency. Gearboxes allow engineers to tailor torque and speed to the application.

Common gearbox pairings include:

- Planetary gearboxes – compact, high load capacity.

- Harmonic drives – precision robotics.

- Cycloidal gearboxes – high-shock load resistance.

Benefits of AFM-Gearbox Integration

- Torque Amplification – Enables smaller AFMs to drive heavy loads.

- Flexibility – Gear ratios provide versatility across varying duty cycles.

- Compact Powertrains – Flat AFMs plus planetary gearboxes reduce system footprint.

Challenges

- Added complexity – More moving parts increase potential failure points.

- Efficiency losses – Gear meshing introduces friction and heat.

- Maintenance requirements – Lubrication, wear monitoring, and servicing.

Case Example: Electric Vehicles

In high-performance EVs, AFMs paired with single- or two-stage gearboxes provide the balance between compact design and road torque demands. Unlike radial flux motors, AFMs reduce overall drivetrain length, freeing space for batteries or passenger comfort.

Axial Flux Direct-Drive Systems

What Is Direct-Drive?

Direct-drive integration eliminates the gearbox. The motor shaft connects directly to the load, relying on the AFM’s intrinsic torque density to deliver required performance.

Benefits

- High Efficiency – No mechanical transmission losses.

- Reliability – Fewer moving parts reduce wear and failure points.

- Precision Control – Ideal for robotics and CNC systems requiring smooth motion.

- Compact Assembly – Reduces overall drivetrain size and weight.

Limitations

- Size and Weight – To produce enough torque without gearing, larger AFMs may be needed.

- Cost – High-performance AFMs with strong permanent magnets can be expensive.

- Thermal Management – Direct-drive AFMs generate significant heat under high torque.

Case Example: Wind Turbines

Direct-drive axial flux generators boost efficiency, cut maintenance, and enhance reliability by eliminating gearboxes.

Engineering Considerations in Integration

Torque-Speed Matching

- With Gearboxes: Designers can select smaller AFMs running at high speed, with gear reduction providing torque.

- Direct-Drive: The AFM must be dimensioned to produce full required torque at low speed.

Cooling and Thermal Management

AFMs typically use liquid cooling or forced air systems due to their high torque density.

In direct-drive systems, cooling becomes more critical because no gearbox dissipates part of the heat.

Efficiency Trade-Offs

- AFM + Gearbox: Motor efficiency (≈95%) × gearbox efficiency (≈90–95%) = combined efficiency ~85–90%.

- Direct-Drive AFM: Efficiency closer to 93–96%, but requires larger motor footprint.

Material Selection

- Magnets: High-grade NdFeB permanent magnets increase torque density.

- Laminations: Thin, high-permeability electrical steel reduces eddy current losses.

- Housing: Lightweight alloys or composites improve system compactness.

Cost Factors

- Direct-drive: Higher initial motor cost, lower lifetime maintenance.

- Gearbox integration: Lower motor cost, but higher lifecycle maintenance costs.

Comparative Analysis

| Factor | AFM + Gearbox | Direct-Drive AFM |

| Efficiency | 85–90% (due to gear losses) | 93–96% (no gear losses) |

| Torque Density | High (gears amplify torque) | Very high (large AFM required) |

| Size/Weight | More compact overall | Larger motor, no gearbox bulk |

| Cost | Lower upfront, higher maintenance | Higher upfront, lower maintenance |

| Reliability | Moderate (gear wear, lubrication) | High (fewer moving parts) |

| Applications | EVs, robotics, industrial machinery | Wind turbines, aerospace, precision drives |

Applications Across Industries

Electric Mobility

AFM + Gearbox: Suited for passenger EVs, motorcycles, and scooters needing dynamic torque curves.

Direct-Drive AFM: Popular in e-bikes and in-wheel EV motors for compact integration.

Aerospace

Lightweight direct-drive AFMs in propulsion fans or actuator systems, where reliability outweighs cost.

Robotics

Harmonic-drive gearboxes plus AFMs enable precise manipulation with compact actuators.

Renewable Energy

Direct-drive axial flux generators in wind turbines reduce maintenance needs compared to gear-driven systems.

Future Trends in Integration

- Advanced Cooling Techniques – Immersion cooling and micro-channel liquid cooling for high-torque AFMs.

- Additive Manufacturing – Custom laminated stacks and rotor designs to optimize direct-drive torque.

- Smart Gearboxes – Integration with sensors for predictive maintenance in AFM-driven systems.

- Rare-Earth-Free Designs –Using ferrite or composites to lessen dependence on critical materials.

- Hybrid Integration – Semi-direct systems with ultra-low-ratio gearboxes (≤2:1) to balance torque and efficiency.

Axial flux motors represent a transformative leap in electric motor technology, offering high torque density and compact form factors that complement both gearbox integration and direct-drive systems. The choice between these pathways depends on the specific application: gearboxes provide flexibility and torque multiplication for mobility and robotics, while direct-drive systems maximize efficiency and reliability in renewable energy and aerospace.

As manufacturing techniques, magnet materials, and thermal management technologies advance, the line between gearbox-assisted and direct-drive axial flux applications will blur, enabling even more efficient, compact, and durable electromechanical systems for the industries of tomorrow.

Washing machines are vital household appliances, offering convenience, efficiency, and reliable cleaning performance worldwide. While most people are familiar with the drum, detergent drawer, and water inlet, the drain motor is one of the most important yet often overlooked components. Without it, dirty water would remain trapped in the tub, preventing the wash cycle from completing properly.

This guide explores how a drain motor works in washing machines, its components, working principles, maintenance tips, and troubleshooting techniques. Whether you are an appliance repair technician, an engineering student, or a curious homeowner, this article will give you a complete understanding of the drain motor’s role.

What is a Drain Motor in a Washing Machine?

The drain motor, also called the drain pump, expels dirty water from the washer after washing and rinsing cycles. It works in combination with the drain pump assembly, hoses, and control circuitry to ensure water flows out to the household drain system.

Key Functions:

- Removes dirty water after the wash cycle.

- Expels rinse water after the rinse phase.

- Prepares the tub for spinning by eliminating excess water.

- Prevents water stagnation that could cause odors or mold.

Types of Drain Motors

While the core function remains the same, drain motors vary depending on washing machine design and manufacturer.

| Drain Motor Type | Description | Common Usage |

| Synchronous AC Motor | Uses alternating current to drive the pump impeller at a fixed speed. | Common in front-load machines. |

| Universal Motor | Operates on AC or DC, higher speed capability. | Found in some high-speed draining models. |

| DC Brushless Motor | Uses electronic commutation for quiet and efficient operation. | Used in premium energy-efficient machines. |

Main Components of a Drain Motor System

Understanding the parts of a drain motor assembly is key to understanding its operation.

Motor Housing

Shields internal parts from water, dust, and physical damage to ensure reliable operation.

Rotor and Stator

- Rotor: The rotating component that drives the impeller.

- Stator: The stationary coil assembly that creates the magnetic field.

Impeller

A small fan-like structure connected to the rotor that pushes water through the drain hose.

Shaft Seal

Prevents water from leaking into the motor chamber.

Electrical Connector

Links the motor to the washing machine control board or timer.

Drain Pump Housing

Houses the impeller and channels water flow from the tub directly into the drain hose.

How a Drain Motor Works – Step-by-Step Process

Let’s explore the step-by-step operation of a washing machine drain motor during its cycle.

Step 1: Control Signal Activation

At the end of a wash or rinse cycle, the washing machine control board sends an electrical signal to the drain motor.

Step 2: Motor Rotation

The motor starts spinning the impeller, which generates a centrifugal force that moves water from the tub into the pump chamber.

Step 3: Water Movement

The spinning impeller pushes water into the drain hose, which is connected to the household drain pipe.

Step 4: Tub Emptying

The motor continues running until water level sensors or timers indicate the tub is empty.

Step 5: Automatic Shut-off

Once draining is complete, the motor stops to conserve energy and prepare for the next cycle.

The Science Behind the Drain Motor

Electromagnetic Operation

Most drain motors generate a rotating magnetic field via stator coils, which then drives the rotor to pump water.

Hydrodynamic Pumping

The impeller uses hydrodynamic principles to convert rotational energy into kinetic energy, pushing water out through the pump housing.

Synchronous vs. Asynchronous Operation

Synchronous motors maintain a fixed speed matching the power supply frequency.

Asynchronous motors can have slight speed variations depending on load.

Drain Motor in Different Washing Machine Types

Front-Load Washing Machines

Use high-efficiency AC drain motors.

Often incorporate filter traps to catch debris before it reaches the impeller.

Top-Load Washing Machines

May use simpler universal motors.

Pump assembly may be integrated into the transmission housing in older designs.

Compact or Portable Washers

Low-power DC motors enhance energy efficiency while ensuring quiet, smooth operation in washing machines.

Common Problems with Drain Motors

| Problem | Possible Cause | Symptoms |

| Motor not running | Electrical fault, blown fuse, faulty control board | Machine won’t drain |

| Loud noise during draining | Damaged impeller, debris in pump housing | Grinding or rattling sound |

| Slow draining | Clogged hose or filter | Water remains in tub after cycle |

| Leaks | Worn shaft seal or cracked pump housing | Water under machine |

Maintenance Tips for Long Motor Life

Regularly clean the filter to avoid debris buildup.

Check drain hoses regularly for any kinks or blockages.

Run periodic cleaning cycles with descaling solution to prevent limescale buildup.

Avoid overloading the machine, which can cause excess strain on the motor.

Troubleshooting a Faulty Drain Motor

Safety First

Disconnect the washing machine from its electrical power source.

Turn off the washing machine’s main water supply.

Steps to Diagnose

- Check the Filter – Remove and clean any lint or debris.

- Inspect the Impeller – Check for any cracks, chips, blockages, or visible damage.

- Test Electrical Continuity – Check coil resistance using a multimeter for accurate measurement.

- Examine Wiring – Look for loose or corroded connectors.

Replacement

If the motor is faulty:

- Disconnect the wiring harness.

- Remove the mounting screws.

- Replace with a compatible OEM or high-quality aftermarket motor.

Energy Efficiency and Modern Innovations

Modern washing machines focus not only on effective water removal but also on energy savings and quiet operation.

Brushless DC Motors

Consume less electricity.

Operate with less vibration and noise.

Smart Control Integration

Variable-speed draining based on water load.

Self-diagnostic features to detect clogs or motor faults.

Eco-Drain Technology

Some premium washers reuse warm rinse water for the next wash cycle, requiring precise motor control to partially drain.

Comparing Drain Motor Designs

| Feature | Synchronous AC | Universal | Brushless DC |

| Efficiency | High | Moderate | Very high |

| Noise | Low | Moderate | Very low |

| Durability | High | Moderate | High |

| Cost | Moderate | Low | High |

Lifespan of a Drain Motor

On average, a drain motor lasts 5–10 years, depending on:

- Usage frequency.

- Water quality (hard water shortens life).

- Maintenance practices.

Signs of end-of-life include frequent clogging, overheating, and increased noise.

The drain motor is a vital component that ensures your washing machine completes its cycles efficiently by removing water at the right times. Understanding how it works—along with proper maintenance and timely repairs—can extend its lifespan, improve washing machine performance, and prevent costly breakdowns.

Whether you’re dealing with a front-load, top-load, or portable washer, the drain motor’s operating principles remain largely the same: convert electrical energy into mechanical motion to pump water away from the tub. With the rise of energy-efficient brushless designs and smart diagnostic features, modern drain motors are becoming more reliable, quieter, and more sustainable than ever before.

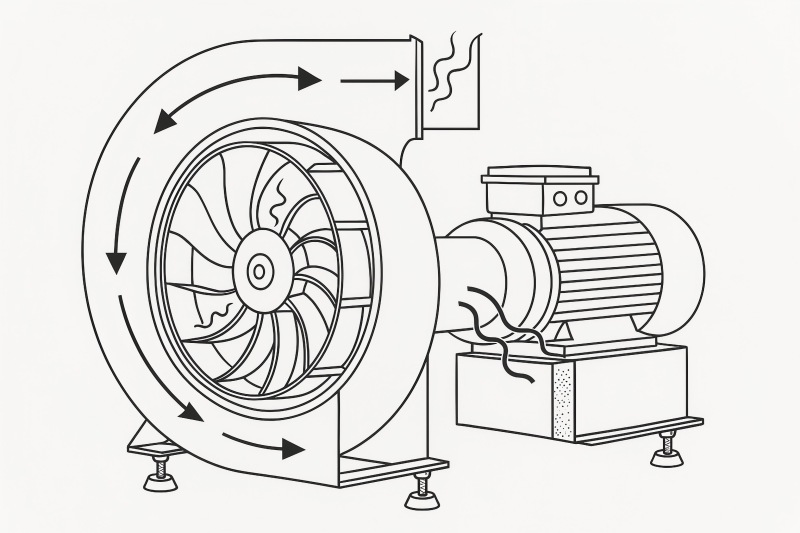

Electronically Commutated (EC) centrifugal fans have become a preferred choice for HVAC systems, data centers, air handling units, and cleanroom environments due to their energy efficiency, precise speed control, and compact design. While these fans already offer quieter operation than many AC alternatives, noise reduction remains a critical engineering priority—especially in applications where comfort, productivity, or compliance with environmental noise regulations is essential.

Fan noise can affect human comfort, disrupt sensitive equipment, and even contribute to long-term hearing damage in high-intensity industrial environments. Therefore, integrating noise reduction technologies into EC centrifugal fan design is not just a performance enhancement—it is a necessity.

Noise Sources in EC Centrifugal Fans

Before applying noise control solutions, it is essential to first determine the sources of fan noise. In EC centrifugal fans, noise is typically categorized into aerodynamic, mechanical, and electrical sources.

Aerodynamic Noise

- Blade Passing Frequency (BPF): Caused by blades cutting through the air, creating pressure fluctuations.

- Turbulence: Generated by airflow separation, vortex shedding, and wake interactions.

- Inlet and Outlet Disturbances: Poor duct design can cause additional turbulence and noise.

Mechanical Noise

- Bearing Noise: Friction and imperfections in bearings generate vibration and tonal noise.

- Structural Resonance: Fan housings and mounts can amplify mechanical vibrations.

Electrical Noise

- Motor Commutation: Although EC motors use electronic commutation, switching transients can produce high-frequency tonal noise.

- Electromagnetic Vibration: Interaction between magnetic fields and rotor/stator components may cause audible hum.

Key Parameters Affecting Noise in EC Fans

Understanding the parameters influencing noise generation helps in selecting the right noise reduction strategies:

| Parameter | Influence on Noise |

| Blade Design | Shapes airflow, affects turbulence and tonal components |

| Tip Clearance | Impacts vortex formation and high-frequency noise |

| Fan Speed | Higher speed increases both tonal and broadband noise |

| Housing Geometry | Poor design increases flow separation and turbulence |

| Motor Control Method | Switching frequency impacts tonal electrical noise |

Aerodynamic Noise Reduction Technologies

Optimized Blade Profiles

Using airfoil-shaped blades reduces turbulence and increases aerodynamic efficiency. Today’s CFD technology enables engineers to:

Minimize stall points.

Reduce flow separation.

Smooth pressure gradients across the blade.

Example: Some EC centrifugal fans use backward-curved blades with optimized curvature to reduce vortex shedding.

Blade Count and Spacing Adjustments

Altering blade number changes the blade passing frequency, potentially moving tonal peaks away from sensitive frequency ranges.

Uneven blade spacing can spread noise energy across multiple frequencies, making it less perceptible.

Diffuser and Guide Vanes

Guide vanes straighten airflow after the impeller, reducing swirl and turbulence at the outlet. This minimizes broadband noise and improves static pressure recovery.

Inlet and Outlet Design Improvements

Bellmouth inlets smooth the air entry, reducing turbulence at the leading edge.

Flared or aerodynamic outlets help maintain laminar flow, lowering noise from sudden expansion.

Mechanical Noise Reduction Technologies

High-Precision Bearings

Low-noise, high-quality ball or sleeve bearings with optimized lubrication reduce friction-induced noise. Some EC fan manufacturers use ceramic hybrid bearings for lower vibration.

Vibration Isolation Mounts

Rubber, silicone, or spring mounts reduce structure-borne vibration transmission.

Particularly effective when fans are mounted in rigid HVAC frames.

Structural Damping

Applying damping materials (e.g., constrained layer damping sheets) to the fan housing reduces resonance amplification.

Electrical Noise Reduction Technologies

High-Switching-Frequency Drives

Increasing PWM (pulse-width modulation) switching frequency above the human audible range (>20 kHz) eliminates tonal switching noise.

Sinusoidal Commutation

Replacing traditional trapezoidal commutation with sinusoidal control smooths torque ripple, reducing both mechanical vibration and audible electrical hum.

Shielding and Filtering

Electromagnetic shielding and proper grounding reduce radiated electrical noise that can be picked up acoustically by other components.

Acoustic Treatment Technologies

Sound-Absorbing Materials

Acoustic foams inside the fan enclosure absorb high-frequency noise.

Fiberglass or mineral wool liners in ducts reduce broadband noise.

Silencers and Attenuators

Reactive silencers target tonal noise using resonators.

Dissipative silencers reduce broadband noise via absorption.

Enclosures and Acoustic Barriers

Placing fans inside an acoustic enclosure with soundproofing materials can drastically reduce radiated noise, though it must be balanced with cooling requirements.

Active Noise Control (ANC) in EC Fans

ANC systems use microphones, speakers, and digital processors to generate anti-phase sound waves that cancel unwanted noise. While more common in duct systems than individual fans, ANC can:

- Target specific tonal frequencies (e.g., blade passing frequency).

- Reduce low-frequency noise that passive materials struggle to absorb.

Control Strategy Optimization

Since EC motors offer precise speed control, intelligent fan speed management can be a noise reduction strategy:

- Variable Speed Operation: Reducing fan speed during low load periods decreases aerodynamic and mechanical noise.

- Soft Start/Stop: Gradual acceleration and deceleration reduce transient noise spikes.

- Load Matching: Avoiding operation near resonance frequencies improves overall noise performance.

Measurement and Validation

Noise reduction strategies must be verified through acoustic testing:

| Test Type | Purpose |

| Sound Power Level (SWL) | Determines total acoustic energy output |

| Sound Pressure Level (SPL) | Measures perceived loudness at specific locations |

| Frequency Spectrum Analysis | Identifies tonal peaks and broadband noise content |

| Vibration Analysis | Detects mechanical resonance sources |

Testing should be conducted in accordance with ISO 3744 (free-field over a reflecting plane) or ISO 5136 (ducted fan noise measurement).

Real-World Application Examples

Case Study 1: Data Center Cooling

A large data center reduced cooling fan noise by:

- Switching from AC to EC centrifugal fans with backward-curved blades.

- Adding inlet bellmouths and duct silencers.

- Increasing PWM frequency to 25 kHz.

Result: 7 dB(A) noise reduction and improved cooling efficiency.

Case Study 2: Hospital HVAC

A hospital air handling unit integrated:

- Acoustic liners in ducts.

- Variable-speed EC fans with sinusoidal commutation.

- Vibration isolation mounts.

Result: Noise level in patient rooms dropped below 35 dB(A).

Comparative Effectiveness of Noise Reduction Methods

| Noise Source | Technology Applied | Typical Reduction (dB) |

| Aerodynamic | Optimized blade profile | 2–5 |

| Aerodynamic | Inlet bellmouth + diffuser | 3–6 |

| Mechanical | High-precision bearings + isolation | 2–4 |

| Electrical | High-frequency PWM + sinusoidal control | 1–3 |

| Acoustic | Silencers and duct liners | 5–10 |

| Active | ANC (targeted tonal frequencies) | 5–15 |

Future Trends in EC Fan Noise Reduction

AI-Based Acoustic Optimization

Machine learning models can analyze real-time noise spectra and adjust fan speed, blade pitch (in variable-pitch designs), or ANC parameters dynamically.

Additive Manufacturing for Blade Design

3D printing allows highly complex blade geometries that improve aerodynamics and reduce turbulence.

Integrated Acoustic Sensors

Next-generation EC fans may include built-in microphones to monitor noise performance and trigger maintenance alerts continuously.

Noise reduction in EC centrifugal fans is achieved through a combination of aerodynamic optimization, mechanical isolation, electronic control refinement, and acoustic treatment. While each technology offers its own benefits, the most effective solutions combine multiple strategies tailored to the specific application.

By integrating noise control early in the design phase—and validating through standardized acoustic testing—manufacturers and system integrators can ensure that EC centrifugal fans deliver not only energy efficiency and reliability but also a quieter, more comfortable operating environment.