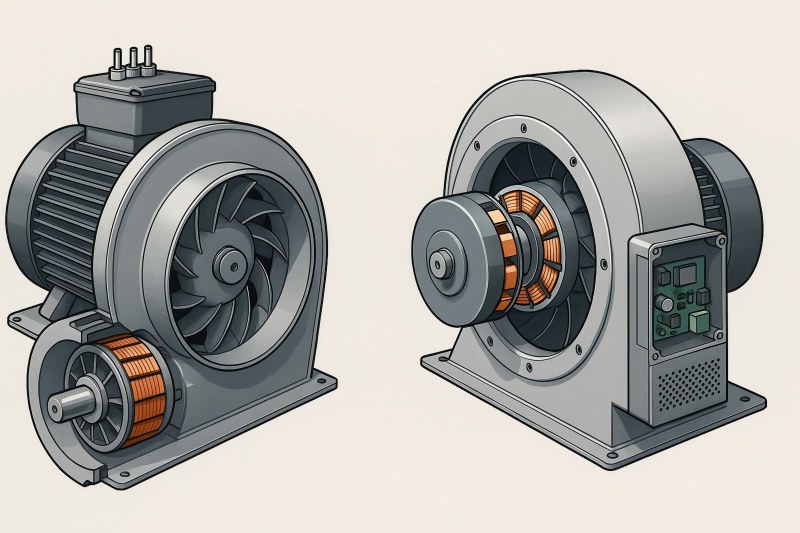

Centrifugal fans serve HVAC, industrial ventilation, clean rooms, electronics cooling, and various air-moving uses. They move air radially, changing its direction by 90 degrees and increasing its pressure. Traditionally, AC centrifugal fans—powered by alternating current induction motors—were the standard choice.

However, in the last decade, EC (Electronically Commutated) centrifugal fans, which integrate a brushless DC motor with onboard electronics, have emerged as a high-efficiency alternative.

Choosing between EC and AC centrifugal fans involves balancing performance, efficiency, cost, and application requirements. This article examines their differences in depth, providing data, examples, and recommendations.

AC Centrifugal Fans

- Driven by asynchronous induction motors powered directly from the AC mains.

- Speed is determined by supply frequency (50 Hz or 60 Hz) and motor pole count.

- Speed control requires additional devices (e.g., VFDs or voltage regulators).

Key Features:

- Simple, robust design.

- Long-established technology.

- Lower initial cost.

EC Centrifugal Fans

- Use brushless DC motors with integrated AC-to-DC conversion electronics.

- Speed control is built-in and managed electronically.

- Motor commutation is handled via microprocessor-controlled electronics.

Key Features:

- Higher efficiency.

- Integrated speed control.

- Precise airflow management.

How They Work

| Feature | AC Centrifugal Fan | EC Centrifugal Fan |

| Motor Type | Induction motor (single or three-phase) | Brushless DC motor with integrated electronics |

| Power Supply | Direct AC | AC converted to DC internally |

| Speed Control | External (VFD, voltage regulator) | Integrated electronic control |

| Efficiency | 50–70% (typical) | 80–90% (typical) |

| Maintenance | Minimal, but higher wear over long term | Very low, fewer wear parts |

Efficiency and Energy Consumption

AC centrifugal fans have limited efficiency due to:

- Rotor slip losses in induction motors.

- Fixed speed operation.

- Lower power factor at partial load.

- Use permanent magnets → no rotor slip losses.

- Operate with variable speed and optimized control algorithms.

- Provides excellent efficiency across a wide range of operating conditions.

Table 1: Typical Efficiency Comparison

| Motor Power (kW) | AC Fan Efficiency (%) | EC Fan Efficiency (%) |

| 0.5 | 60 | 82 |

| 1.0 | 65 | 85 |

| 2.0 | 68 | 88 |

| 5.0 | 70 | 90 |

Energy Savings Example

Consider a 2 kW fan running 4,000 hours/year:

AC fan: 2 kW × 4,000 h ÷ 0.68 efficiency = 11,764 kWh/year

EC fan: 2 kW × 4,000 h ÷ 0.88 efficiency = 9,091 kWh/year

Annual Savings: 2,673 kWh/year, which could translate to $300–$500/year depending on electricity rates.

Speed Control and Airflow Management

AC Fans

Speed changes require frequency inverters (VFDs) or voltage controllers.

Each method adds cost and may introduce harmonic distortion.

Mechanical dampers are an option but waste energy.

EC Fans

Built-in electronic control allows speed adjustment via:

- 0–10V control signal

- PWM signal

- Modbus or BACnet communication

Allows dynamic adjustment for demand-based ventilation, leading to significant energy savings.

Noise Performance

- AC fans operate at fixed speed, often generating more noise during low demand periods since airflow cannot be reduced without throttling.

- EC fans reduce noise by slowing down during partial load, cutting sound levels significantly.

Table 2: Example Noise Levels

| Operating Mode | AC Fan Noise (dB(A)) | EC Fan Noise (dB(A)) |

| Full Speed | 75 | 74 |

| 70% Speed | 75 (throttled) | 66 |

| 50% Speed | 75 (throttled) | 60 |

Maintenance and Reliability

AC Fans

- Consistent performance under tough industrial conditions.

- Bearings require periodic inspection/lubrication.

- Motor winding insulation can degrade over decades.

EC Fans

- Fewer mechanical wear parts (no brushes).

- Electronics are the main wear point—quality design is crucial.

- Often have longer service intervals but can be more complex to repair.

Cost Considerations

Initial Purchase Cost

AC centrifugal fans: 20–40% lower upfront price.

EC centrifugal fans: Higher due to integrated electronics and permanent magnet motors.

Lifetime Cost

When factoring in energy savings and maintenance, EC fans often have a lower total cost of ownership (TCO).

Example ROI Calculation (2 kW fan):

- AC Fan Cost: $1,000

- EC Fan Cost: $1,400

- Annual Energy Savings: $350

- Payback Period: (1,400 – 1,000) ÷ 350 ≈ 1.14 years

Environmental Impact

EC fans contribute to:

Lower CO₂ emissions due to reduced energy use.

Compliance with efficiency regulations like EU Ecodesign Directive (ErP) or U.S. DOE fan efficiency rules.

Applications and Suitability

AC Fans: Best For

- Heavy-duty industrial settings where speed variation is not critical.

- Harsh environments where electronics may fail prematurely.

- Budget-sensitive projects.

EC Fans: Best For

- Commercial buildings requiring variable air volume (VAV) control.

- Data centers, cleanrooms, and laboratories where precise airflow is critical.

- Energy-efficient retrofits to meet green building standards.

Comparative Summary Table

| Factor | AC Centrifugal Fan | EC Centrifugal Fan |

| Efficiency | 50–70% | 80–90% |

| Speed Control | External device required | Integrated |

| Noise Control | Limited | Excellent at partial load |

| Maintenance | Low to medium | Low |

| Initial Cost | Low | Higher |

| TCO | Higher (over lifetime) | Lower (energy savings) |

| Best Use Case | Fixed-speed, industrial | Variable-speed, efficiency-driven |

Real-World Example: Data Center Ventilation Upgrade

A data center replaced 20 × 2 kW AC centrifugal fans with EC versions:

- Energy savings: 2,673 kWh/year/fan → 53,460 kWh/year total

- Annual cost savings: ~$8,000 (at $0.15/kWh)

- CO₂ reduction: ~25 metric tons/year

- Payback: 1.5 years

Decision-Making Framework

When choosing between EC and AC centrifugal fans, consider:

- Operating Hours – High operating hours favor EC fans for ROI.

- Airflow Variability – If demand fluctuates, EC offers more control and savings.

- Budget Constraints – AC may be better for short-term, low-cost installations.

- Environment – Harsh, high-temperature environments may still favor AC fans unless EC is specifically designed for such conditions.

- Regulatory Requirements – EC fans may be necessary to meet modern efficiency standards.

Both EC and AC centrifugal fans have valid applications:

AC fans remain reliable, cost-effective choices for fixed-speed, rugged industrial environments.

EC fans shine in energy efficiency, noise reduction, and precision airflow control, making them ideal for commercial, residential, and high-tech facilities.

If energy costs are significant and variable airflow is required, EC centrifugal fans almost always offer a better long-term investment. However, in cost-sensitive, fixed-speed industrial environments, AC centrifugal fans can still be the practical choice.