The global shift toward energy efficiency, precision control, and reduced maintenance costs has accelerated the adoption of Electronically Commutated (EC) centrifugal fans across industries. At the heart of these fans is the Brushless DC (BLDC) motor, a technology that merges the electrical efficiency of DC operation with the convenience of AC mains connectivity through integrated electronics.

While centrifugal fans have long been powered by traditional AC induction motors, the introduction of BLDC motors into fan design has transformed performance possibilities. EC centrifugal fans now offer superior energy efficiency, lower noise, precise airflow control, and extended service life—attributes directly linked to BLDC technology.

What is an EC Centrifugal Fan?

An EC centrifugal fan is a fan that uses a brushless DC motor powered by an integrated electronic control module. The “electronically commutated” part means that instead of using mechanical brushes and a commutator to switch current in the rotor windings, the switching is done electronically via a control circuit.

Key Points:

- Power Input: EC fans are connected to standard AC mains (single-phase 110–240V or three-phase 380–480V).

- Motor Operation: Internally, AC is rectified to DC and supplied to the BLDC motor windings.

- Speed Control: Controlled by pulse-width modulation (PWM), 0–10V analog signal, or digital protocols like Modbus or BACnet.

- Airflow Generation: The centrifugal impeller accelerates air radially outward, creating a pressure rise for ducted systems.

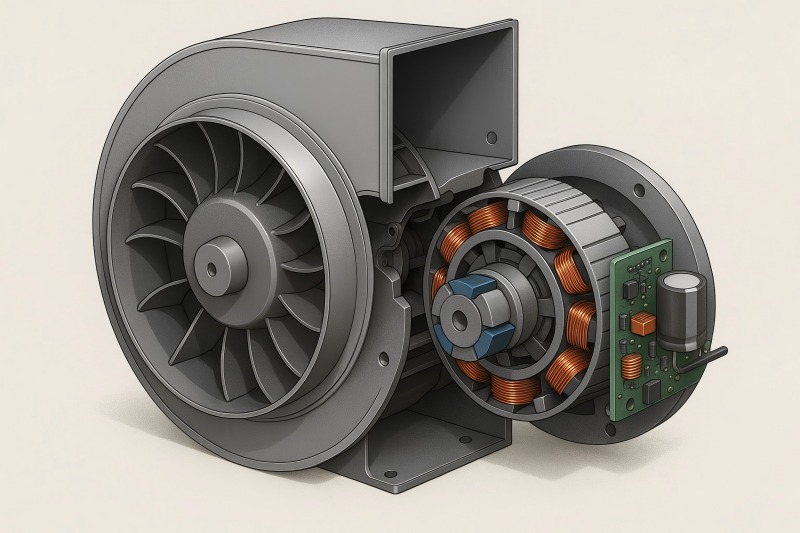

Inside the BLDC Motor

A Brushless DC motor inside an EC fan consists of:

- Stator – Laminated steel core with copper windings, forming the stationary part of the motor.

- Rotor – Permanent magnets mounted on a shaft, replacing rotor windings found in AC induction motors.

- Position Sensors – Detection of rotor position using Hall-effect sensors or through sensorless control algorithms.

- Electronic Controller (ECU) – Rectifies AC to DC, manages commutation, regulates speed, and controls torque.

Rotor

Uses rare-earth permanent magnets (typically NdFeB) for high magnetic flux density.

No rotor copper windings → eliminates rotor I²R losses.

Light rotor reduces rotational inertia for faster speed changes.

Stator

Wound with enamelled copper wire.

Optimized slot fill factor for higher efficiency.

Often designed with skewed slots to reduce cogging torque.

Commutation

Performed electronically rather than mechanically.

Switches current in windings in sync with rotor position to maintain torque production.

Two main methods: trapezoidal (block) commutation and sinusoidal commutation.

- Trapezoidal: Simple, good for cost-sensitive applications.

- Sinusoidal: Smoother torque, lower noise, ideal for HVAC fans.

How BLDC Motors Work in EC Fans

Power Conversion Path

- AC Input: From mains power supply.

- Rectification: AC is converted to DC using a diode bridge or rectifier.

- DC Bus: Filters and capacitors smooth DC voltage.

- Inverter Stage: High-speed switching (MOSFETs or IGBTs) generates 3-phase AC for the BLDC motor.

- Electronic Commutation: Controller adjusts phase timing based on rotor position feedback.

- Output Control: Matches fan speed to required airflow or pressure setpoint.

Why BLDC Motors Excel in EC Centrifugal Fans

Efficiency

BLDC motors achieve 80–90% efficiency compared to 60–75% for equivalent AC induction motors.

Reduced rotor losses and optimized winding design.

Speed Control

Smooth variable-speed control from 20% to 100% of rated speed.

High part-load efficiency—important for HVAC systems with variable airflow demands.

Noise Reduction

Sinusoidal commutation minimizes torque ripple.

Precise control reduces mechanical vibration and aerodynamic noise.

Compactness

Higher torque per volume allows smaller motors for the same output.

Eliminates bulky external VFDs by integrating control electronics.

Performance Comparison: AC Induction vs BLDC in Centrifugal Fans

| Parameter | AC Induction Motor Fan | BLDC Motor EC Fan |

| Motor Efficiency | 60–75% | 80–90% |

| Speed Control Range | Limited without VFD | Wide (integrated control) |

| Torque at Low Speed | Reduced | Maintained |

| Heat Generation | Higher | Lower |

| Noise Level | Higher at part load | Lower due to smoother commutation |

| Maintenance | Bearings only | Bearings only |

| Power Factor | 0.6–0.85 | >0.95 |

Design Considerations for BLDC Motors in EC Fans

Motor Sizing

Must handle peak torque during startup and transient load changes.

Oversizing slightly can improve thermal performance and extend lifespan.

Thermal Management

BLDC motors generate less heat, but integrated electronics require cooling.

Common methods: heat sinks on controller housing, forced airflow from impeller.

Magnet Selection

NdFeB offers highest performance but can lose magnetism at high temperatures (>150°C).

For high-heat applications, SmCo magnets may be used.

Control Algorithms

Field-Oriented Control (FOC) for optimal torque and efficiency.

Sensorless control for lower cost, but Hall sensors often preferred for high reliability in HVAC.

Integration with Fan Aerodynamics

BLDC motors enable new aerodynamic optimizations in EC centrifugal fans:

- Direct-drive design eliminates belts and pulleys, improving mechanical efficiency.

- Lower rotor inertia allows adaptive speed changes to meet real-time airflow demands.

- Integration with variable inlet vanes or EC impeller blades for peak performance.

Application

Commercial HVAC Systems

Fans for supply and return airflow in air handling units

Demand-controlled ventilation with CO₂ or occupancy sensors.

Data Centers

Precise temperature and pressure control for server room cooling.

EC fans integrated into Computer Room Air Conditioning units.

Refrigeration and Cooling Towers

Variable-speed fans reduce energy use during cooler ambient conditions.

Improved defrost cycles.

Cleanrooms & Laboratories

Low-noise, precision airflow for controlled environments.

Energy Savings Example

Consider a 5 kW centrifugal fan running 6,000 hours/year:

AC Induction Fan Efficiency: 70%

Input = 7.14 kW

Annual Energy Use = 42,840 kWh

BLDC EC Fan Efficiency: 88%

Input = 5.68 kW

Annual Energy Use = 34,080 kWh

Savings: 8,760 kWh/year (~$1,050/year at $0.12/kWh)

CO₂ Reduction: ~6.2 metric tons/year (based on 0.7 kg CO₂/kWh grid emission factor)

Reliability and Maintenance

No brushes → no brush wear, less downtime.

Bearings remain the only major wear component.

Electronics are designed for 40,000–60,000 hour lifespans but require protection from moisture and surges.

Industry Standards and Compliance

BLDC-powered EC fans often meet or exceed:

- EU ErP Directive for fan efficiency.

- US DOE Fan Energy Index (FEI) requirements.

- ISO 5801 (airflow performance testing).

- IEC 60034-30-2 for motor efficiency classification.

Future Trends

Wide Bandgap Semiconductors (SiC, GaN): Improve inverter efficiency and reduce controller size.

Sensorless High-Precision Control: For cost and reliability improvements.

IoT Integration: Remote monitoring, predictive maintenance, real-time optimization.

The Brushless DC motor is the technological backbone of EC centrifugal fans, delivering unmatched efficiency, control precision, and operational flexibility. By replacing mechanical commutation with electronics and integrating advanced motor control algorithms, BLDC motors enable fans to meet modern demands for energy savings, noise reduction, and adaptability.

When selecting centrifugal fans:

Choose BLDC EC fans for applications requiring variable speed, high efficiency, and precise control—such as HVAC, data centers, and clean environments.

Expect higher upfront costs, but significant lifecycle savings in energy and maintenance.

The industry trend is clear: as energy regulations tighten and technology costs fall, BLDC-powered EC centrifugal fans are set to become the new standard in air movement technology.