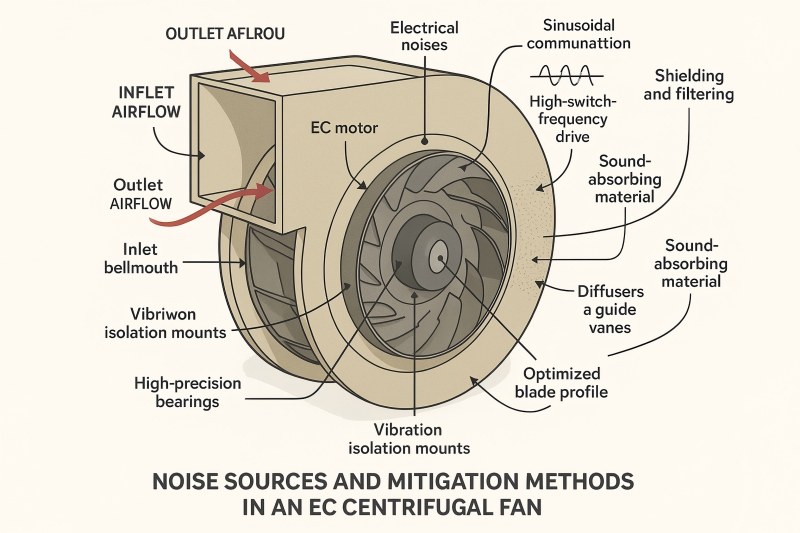

Electronically Commutated (EC) centrifugal fans have become a preferred choice for HVAC systems, data centers, air handling units, and cleanroom environments due to their energy efficiency, precise speed control, and compact design. While these fans already offer quieter operation than many AC alternatives, noise reduction remains a critical engineering priority—especially in applications where comfort, productivity, or compliance with environmental noise regulations is essential.

Fan noise can affect human comfort, disrupt sensitive equipment, and even contribute to long-term hearing damage in high-intensity industrial environments. Therefore, integrating noise reduction technologies into EC centrifugal fan design is not just a performance enhancement—it is a necessity.

Noise Sources in EC Centrifugal Fans

Before applying noise control solutions, it is essential to first determine the sources of fan noise. In EC centrifugal fans, noise is typically categorized into aerodynamic, mechanical, and electrical sources.

Aerodynamic Noise

- Blade Passing Frequency (BPF): Caused by blades cutting through the air, creating pressure fluctuations.

- Turbulence: Generated by airflow separation, vortex shedding, and wake interactions.

- Inlet and Outlet Disturbances: Poor duct design can cause additional turbulence and noise.

Mechanical Noise

- Bearing Noise: Friction and imperfections in bearings generate vibration and tonal noise.

- Structural Resonance: Fan housings and mounts can amplify mechanical vibrations.

Electrical Noise

- Motor Commutation: Although EC motors use electronic commutation, switching transients can produce high-frequency tonal noise.

- Electromagnetic Vibration: Interaction between magnetic fields and rotor/stator components may cause audible hum.

Key Parameters Affecting Noise in EC Fans

Understanding the parameters influencing noise generation helps in selecting the right noise reduction strategies:

| Parameter | Influence on Noise |

| Blade Design | Shapes airflow, affects turbulence and tonal components |

| Tip Clearance | Impacts vortex formation and high-frequency noise |

| Fan Speed | Higher speed increases both tonal and broadband noise |

| Housing Geometry | Poor design increases flow separation and turbulence |

| Motor Control Method | Switching frequency impacts tonal electrical noise |

Aerodynamic Noise Reduction Technologies

Optimized Blade Profiles

Using airfoil-shaped blades reduces turbulence and increases aerodynamic efficiency. Today’s CFD technology enables engineers to:

Minimize stall points.

Reduce flow separation.

Smooth pressure gradients across the blade.

Example: Some EC centrifugal fans use backward-curved blades with optimized curvature to reduce vortex shedding.

Blade Count and Spacing Adjustments

Altering blade number changes the blade passing frequency, potentially moving tonal peaks away from sensitive frequency ranges.

Uneven blade spacing can spread noise energy across multiple frequencies, making it less perceptible.

Diffuser and Guide Vanes

Guide vanes straighten airflow after the impeller, reducing swirl and turbulence at the outlet. This minimizes broadband noise and improves static pressure recovery.

Inlet and Outlet Design Improvements

Bellmouth inlets smooth the air entry, reducing turbulence at the leading edge.

Flared or aerodynamic outlets help maintain laminar flow, lowering noise from sudden expansion.

Mechanical Noise Reduction Technologies

High-Precision Bearings

Low-noise, high-quality ball or sleeve bearings with optimized lubrication reduce friction-induced noise. Some EC fan manufacturers use ceramic hybrid bearings for lower vibration.

Vibration Isolation Mounts

Rubber, silicone, or spring mounts reduce structure-borne vibration transmission.

Particularly effective when fans are mounted in rigid HVAC frames.

Structural Damping

Applying damping materials (e.g., constrained layer damping sheets) to the fan housing reduces resonance amplification.

Electrical Noise Reduction Technologies

High-Switching-Frequency Drives

Increasing PWM (pulse-width modulation) switching frequency above the human audible range (>20 kHz) eliminates tonal switching noise.

Sinusoidal Commutation

Replacing traditional trapezoidal commutation with sinusoidal control smooths torque ripple, reducing both mechanical vibration and audible electrical hum.

Shielding and Filtering

Electromagnetic shielding and proper grounding reduce radiated electrical noise that can be picked up acoustically by other components.

Acoustic Treatment Technologies

Sound-Absorbing Materials

Acoustic foams inside the fan enclosure absorb high-frequency noise.

Fiberglass or mineral wool liners in ducts reduce broadband noise.

Silencers and Attenuators

Reactive silencers target tonal noise using resonators.

Dissipative silencers reduce broadband noise via absorption.

Enclosures and Acoustic Barriers

Placing fans inside an acoustic enclosure with soundproofing materials can drastically reduce radiated noise, though it must be balanced with cooling requirements.

Active Noise Control (ANC) in EC Fans

ANC systems use microphones, speakers, and digital processors to generate anti-phase sound waves that cancel unwanted noise. While more common in duct systems than individual fans, ANC can:

- Target specific tonal frequencies (e.g., blade passing frequency).

- Reduce low-frequency noise that passive materials struggle to absorb.

Control Strategy Optimization

Since EC motors offer precise speed control, intelligent fan speed management can be a noise reduction strategy:

- Variable Speed Operation: Reducing fan speed during low load periods decreases aerodynamic and mechanical noise.

- Soft Start/Stop: Gradual acceleration and deceleration reduce transient noise spikes.

- Load Matching: Avoiding operation near resonance frequencies improves overall noise performance.

Measurement and Validation

Noise reduction strategies must be verified through acoustic testing:

| Test Type | Purpose |

| Sound Power Level (SWL) | Determines total acoustic energy output |

| Sound Pressure Level (SPL) | Measures perceived loudness at specific locations |

| Frequency Spectrum Analysis | Identifies tonal peaks and broadband noise content |

| Vibration Analysis | Detects mechanical resonance sources |

Testing should be conducted in accordance with ISO 3744 (free-field over a reflecting plane) or ISO 5136 (ducted fan noise measurement).

Real-World Application Examples

Case Study 1: Data Center Cooling

A large data center reduced cooling fan noise by:

- Switching from AC to EC centrifugal fans with backward-curved blades.

- Adding inlet bellmouths and duct silencers.

- Increasing PWM frequency to 25 kHz.

Result: 7 dB(A) noise reduction and improved cooling efficiency.

Case Study 2: Hospital HVAC

A hospital air handling unit integrated:

- Acoustic liners in ducts.

- Variable-speed EC fans with sinusoidal commutation.

- Vibration isolation mounts.

Result: Noise level in patient rooms dropped below 35 dB(A).

Comparative Effectiveness of Noise Reduction Methods

| Noise Source | Technology Applied | Typical Reduction (dB) |

| Aerodynamic | Optimized blade profile | 2–5 |

| Aerodynamic | Inlet bellmouth + diffuser | 3–6 |

| Mechanical | High-precision bearings + isolation | 2–4 |

| Electrical | High-frequency PWM + sinusoidal control | 1–3 |

| Acoustic | Silencers and duct liners | 5–10 |

| Active | ANC (targeted tonal frequencies) | 5–15 |

Future Trends in EC Fan Noise Reduction

AI-Based Acoustic Optimization

Machine learning models can analyze real-time noise spectra and adjust fan speed, blade pitch (in variable-pitch designs), or ANC parameters dynamically.

Additive Manufacturing for Blade Design

3D printing allows highly complex blade geometries that improve aerodynamics and reduce turbulence.

Integrated Acoustic Sensors

Next-generation EC fans may include built-in microphones to monitor noise performance and trigger maintenance alerts continuously.

Noise reduction in EC centrifugal fans is achieved through a combination of aerodynamic optimization, mechanical isolation, electronic control refinement, and acoustic treatment. While each technology offers its own benefits, the most effective solutions combine multiple strategies tailored to the specific application.

By integrating noise control early in the design phase—and validating through standardized acoustic testing—manufacturers and system integrators can ensure that EC centrifugal fans deliver not only energy efficiency and reliability but also a quieter, more comfortable operating environment.