Drain Valve for Home Appliances

Our drain valve features a durable valve body and a reliable electromagnet to accurately control the water flow.

By adjusting the electromagnetic field, it enables automatic drainage, ensuring efficient, durable, leak-free performance in washing machines, dishwashers, HVAC units, and sweeping robots.

- Rated Voltage: 110~220 VAC

- Structural Design: Flapper, Plunger

- Control Mechanism: Timer-controlled, Sensor-controlled

- Noise Level: ≤ 50 dB(A)

- Insulation Class: E

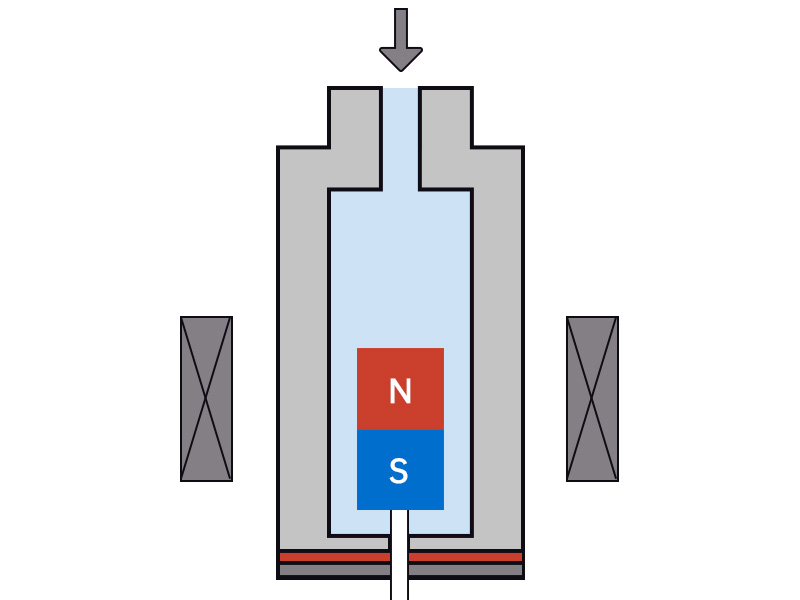

Drain Valve Structure

- An electromagnet, valve body, plunger, seal ring, coil housing, terminals, and bracket make up our drain valve, which allows for regulated, leak-free drainage.

- Electromagnet: Produces magnetic force to actuate valve switch and control water flow accurately.

- Valve Body: Guides water flow and houses internal seals for consistent, leak-free operation.

- Coil Housing: Encloses and protects coil from dust, moisture, and mechanical impact.

- Plunger/Piston: Moves under electromagnetic force to open or block water channel.

- Seal Ring: Ensures tight sealing between parts to prevent any water leakage.

- Connector Terminals: Provides electrical connection for receiving signals from the appliance.

- Mounting Bracket: Holds the valve securely in place inside the appliance structure.

By Structural Design

Flapper and plunger types of drain valve structural designs provide robust sealing, fast response, and adaptability to a range of drainage applications.

Flapper Type Valve

- Hinged flapper controls flow using pressure or gravity.

- Simple design, fast response, reliable sealing, minimal parts.

- Applied in dishwashers, washers, and HVAC drainage systems.

Plunger Type Valve

- Plunger moves vertically to open or close flow path.

- Durable, quick-acting, strong seal, suits electromagnetic actuation.

- Used in washers, auto drain systems needing tight seal.

By Control Mechanism

Control mechanisms for drain valves include timer-controlled and sensor-controlled models, enabling automated, effective, application-specific draining.

Timer-controlled Drain Valve

- Drains fluid automatically at fixed, preset time intervals.

- Used in compressors, condensate lines, and timed systems.

- Provides scheduled drainage, saves energy, enables unattended operation.

Sensor-controlled Drain Valve

- Responds to fluid level, pressure, or temperature sensors.

- Suited for smart appliances and adaptive drain systems.

- Enables responsive, efficient, and low-maintenance fluid control.

By Installation Type

For exterior or internal drainage, drain valves by installation type include built-in and inline alternatives, guaranteeing flexibility, safety, and space efficiency.

Inline Drain Valve

- Mounted directly on pipeline for continuous drainage control.

- Used in HVAC, compressors, and external fluid systems.

- Easy to maintain, replace, and adapt to pipes.

Built-in Drain Valve

- Installed inside equipment for internal fluid discharge.

- Applied in washers, dishwashers, and compact appliances.

- Saves space, improves design, protects from external damage.

Featured Products

DF3 Drain Valve

- Resistance (Phase at 25°C): 120 Ω

- Endplay: 7.5 / 42.5°

- Reduction Ratio: 1 / 42.5

Applications

Our drain valves are used in washers, dishwashers, robots, and AC units for efficient, automated, and protective wastewater drainage management.

Washing Machines

- Controls wastewater discharge efficiently during washing cycles, ensuring proper drainage, preventing overflow, and supporting automated cleaning performance and hygiene.

Dishwashers

- Enables timely drainage of dirty water after washing, improving cycle efficiency, cleanliness, and protecting internal components from moisture buildup.

Sweeping Robots

- Manages internal wastewater disposal in robotic systems, ensuring uninterrupted cleaning, compact design compatibility, and reliable autonomous operation in confined spaces.

Air Conditioning Outdoor Units

- Regulates condensate drainage from the outdoor unit, preventing water accumulation, system corrosion, and ensuring smooth, maintenance-free long-term operation.

FAQ

1.How is the sealing performance of a Drain Valve ensured?

Sealing is achieved using high-quality rubber or silicone rings and precision machining to minimize leakage under different pressures and temperatures during operation.

2.What software tools are used in Drain Valve design?

CAD and simulation tools like SolidWorks or ANSYS are used to model fluid flow, magnetic fields, and stress conditions before manufacturing.

3.How does the Drain Valve meet appliance safety standards?

Designs follow certifications like CE, UL, or RoHS, using flame-retardant materials, proper insulation, and pressure testing to ensure safety and compliance.

4.How is noise reduced in a Drain Valve design?

Noise is minimized through optimized internal geometry, anti-vibration mounts, and smoother flow channels that reduce turbulence and mechanical contact sounds.

5.What testing is done during Drain Valve production?

Each unit undergoes pressure resistance, insulation, leakage, and actuation cycle testing to verify durability, performance, and compliance with quality standards.

6.What type of actuator is commonly used in a Drain Valve?

Most drain valves use solenoid actuators, which rely on electromagnetic force to drive the internal plunger or diaphragm for quick and accurate operation.