Axial flux motors (AFMs) offer exceptional torque density, a compact form factor, and high efficiency, making them ideal for electric vehicles, aerospace, industrial automation, robotics, and renewable energy applications.

A critical design parameter in AFMs is the winding configuration—how the copper coils are arranged around the stator. Two dominant approaches are:

- Distributed winding (also known as lap winding or distributed armature winding)

- Concentrated winding (also called tooth-coil winding)

The choice between these winding techniques has profound implications on:

-

- Motor efficiency

- Torque ripple

- Manufacturing complexity

- Thermal management

- Cost and weight

Axial Flux Motor Winding

In an axial flux motor:

The stator contains coils that produce an alternating magnetic field when energized.

Permanent magnets on the rotor interact with the field to generate torque.

Unlike radial flux motors, axial flux motors feature a flat, disc-shaped design, with coil placement optimized for magnetic flux flowing axially.The winding configuration determines:

- Slot fill factor (how efficiently copper occupies slot space)

- Inductance and resistance of the coils

- Magnetic flux distribution

- Thermal dissipation efficiency

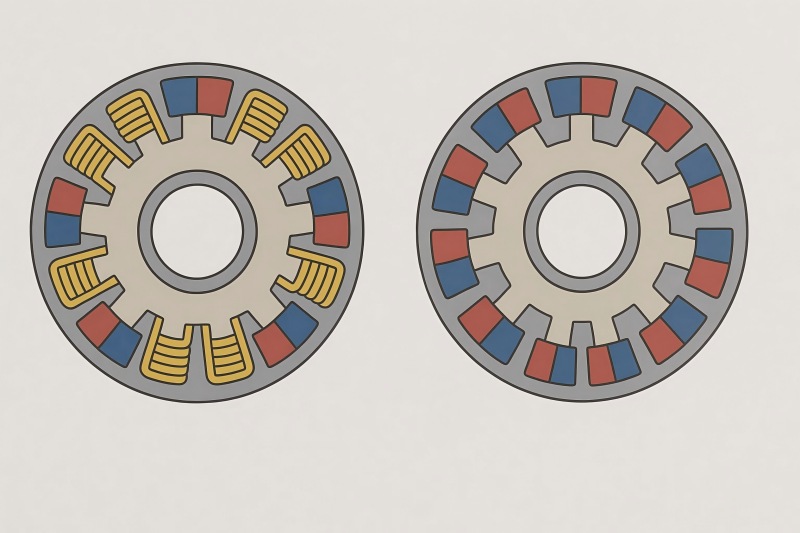

Distributed Winding in Axial Flux Motors

Definition

In distributed winding, the coils are spread over multiple stator slots per pole per phase. Each phase winding is distributed across several slots, resulting in overlapping coil sides.

Example: For a 12-slot, 10-pole motor, a phase winding may span several slots in a wave-like pattern.

Characteristics

- Produces a sinusoidal magnetomotive force (MMF) distribution, reducing harmonic content.

- Higher copper usage compared to concentrated winding.

- More complex coil insertion and end-winding design.

Advantages

- Low harmonic distortion → minimizes eddy current loss within the rotor magnets

- Lower torque ripple → smoother operation.

- Better efficiency at high speed due to reduced core loss from harmonics.

Disadvantages

- Longer end windings → higher copper losses (I²R losses).

- Heavier and bulkier due to more copper.

- More complex manufacturing and winding insertion process.

Concentrated Winding in Axial Flux Motors

Definition

In concentrated winding, each coil is wound around a single tooth or stator pole. The coil sides are concentrated on one tooth rather than distributed over several.

Example: For a 12-slot, 10-pole motor, each tooth carries one complete coil.

Characteristics

- Produces a more trapezoidal MMF waveform, increasing harmonic content.

- Shorter end windings, reducing copper length and weight.

- Easier manufacturing and coil replacement.

Advantages

- Higher slot fill factor → better thermal dissipation and compact design.

- Lower copper usage → reduced resistance, less I²R loss.

- Simpler winding process → suitable for automated manufacturing.

Disadvantages

- Higher torque ripple due to harmonic components.

- Higher AC copper losses at high speeds from increased harmonic currents.

- Requires additional design measures to control eddy current loss in magnets.

Key Performance Metrics: Distributed vs Concentrated

Table 1: Comparison of Distributed and Concentrated Winding in Axial Flux Motors

| Parameter | Distributed Winding | Concentrated Winding |

| MMF waveform | Sinusoidal (low harmonics) | Trapezoidal (high harmonics) |

| Torque Ripple | Low | Higher |

| Copper Usage | Higher (longer end windings) | Lower (shorter end windings) |

| Slot Fill Factor | Medium | High |

| Efficiency at High Speed | Higher | Lower (due to AC losses) |

| Manufacturing Complexity | High | Low |

| Weight | Higher | Lower |

| Thermal Management | More challenging (dense winding) | Easier (compact coil on single tooth) |

| Cost | Higher | Lower |

Electromagnetic Impact of Winding Choice

Harmonics and Losses

Distributed winding minimizes slot harmonics, reducing iron and eddy current losses in rotor magnets.

Concentrated winding increases harmonic content, leading to higher eddy currents, especially in surface-mounted permanent magnets.

Efficiency Trends

Test data for a 5 kW axial flux prototype:

| Winding Type | Peak Efficiency (%) | Torque Ripple (%) | Copper Loss (W) | Core Loss (W) |

| Distributed | 95.2 | 2.5 | 140 | 60 |

| Concentrated | 94.1 | 5.8 | 110 | 85 |

Thermal Management Considerations

Distributed Winding

More copper per slot → higher thermal mass, but longer end windings can be harder to cool.

Requires advanced cooling: forced-air or liquid cooling channels in the stator.

Concentrated Winding

Shorter end windings and compact coils make cooling more direct.

Easier to integrate direct winding cooling (DWC) systems.

Manufacturing and Cost Implications

Distributed Winding

More labor-intensive due to overlapping coil placement.

Ideal for limited runs prioritizing performance over cost

Concentrated Winding

Easier to automate with pre-formed coils.

Preferred in mass production applications like electric two-wheelers, drones, and some EV motors.

Application-Specific Recommendations

| Application | Recommended Winding | Reason |

| High-performance EV traction | Distributed | High efficiency, low torque ripple |

| Light electric vehicles (e-bikes) | Concentrated | Cost-effective, compact, easy to produce |

| Aerospace actuators | Distributed | Precision motion, low noise |

| Drones & UAVs | Concentrated | Lightweight, high torque-to-weight ratio |

| Industrial automation | Distributed | Smooth motion, reduced mechanical vibration |

| Portable tools | Concentrated | Low cost, simplified manufacturing |

Design Optimization Strategies

For Distributed Winding:

- Use fractional-slot winding to further minimize torque ripple.

- Employ skewed slots to reduce cogging torque.

- Optimize end-winding shape to reduce copper loss.

For Concentrated Winding:

- Apply magnet segmentation to reduce eddy current loss from harmonics.

- Use high-resistivity magnet materials (e.g., NdFeB with Dy additions).

- Incorporate fractional-slot concentrated winding (FSCW) to balance harmonic suppression and compactness.

Case Study: EV Axial Flux Motor

Motor Specs:

- Power: 100 kW

- Diameter: 320 mm

- Cooling: Liquid

Distributed Winding Design:

- Efficiency: 96.2% peak

- Torque ripple: 1.8%

- Manufacturing cost index: 1.4

Concentrated Winding Design:

- Efficiency: 94.9% peak

- Torque ripple: 4.5%

- Manufacturing cost index: 1.0

For premium EVs, distributed winding is chosen for its smoothness and efficiency. For budget EVs, concentrated winding offers competitive performance at lower cost.

The choice between distributed and concentrated winding in axial flux motors depends on performance priorities, cost constraints, and application needs:

Distributed winding: Best for applications needing high efficiency, low torque ripple, and smooth operation, though at higher manufacturing cost.

Concentrated winding: Ideal for cost-sensitive, lightweight, and compact designs, especially in mass production.

Future innovations—like fractional-slot distributed winding and segmented magnet designs—are helping bridge performance gaps, allowing engineers to tailor winding configurations more precisely to application requirements.