As the demand for compact, high-efficiency electric drives continues to rise—especially in electric vehicles (EVs), aerospace, robotics, and e-mobility—axial flux motors (AFMs) have gained attention for their superior power and torque density. However, with high performance comes the challenge of heat dissipation. Cooling becomes a critical factor in maintaining performance, reliability, and longevity.

Why Cooling Matters in Axial Flux Motors

Unlike radial flux motors, AFMs have a flat, disc-like structure with a shorter path for magnetic flux and higher surface-area-to-volume ratio. This makes them thermally advantageous but also sensitive to localized heating—especially in high-speed or high-torque applications.

Key thermal concerns include:

- Overheating of windings and permanent magnets

- Efficiency drops due to resistance rise

- Degradation of insulation or materials

- Reduced lifespan or thermal runaway

Heat Sources in Axial Flux Motors

| Source | Description |

| Copper losses (I²R) | Resistance heating in stator windings |

| Iron losses (core losses) | Hysteresis and eddy currents in magnetic cores |

| Eddy currents in magnets | Especially with high switching frequencies |

| Frictional and mechanical | Bearing losses and air drag, though minimal in design |

Thus, the right cooling system is not just a support function—it is essential for unleashing the full power of axial flux motors.

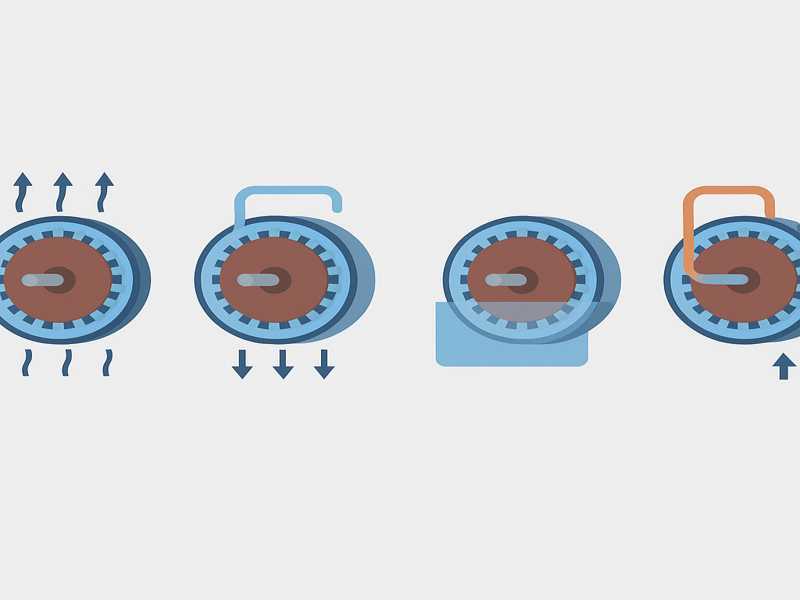

Air Cooling: Simplicity and Cost-Effectiveness

How It Works

Air cooling uses natural or forced convection (fans or airflow channels) to carry away heat from the stator and rotor surfaces.

Natural air cooling: Passive dissipation through ambient airflow

Forced air cooling: Blowers or axial fans push air through motor channels or over fins

| Pros | Cons |

| √ Simple design | × Limited thermal capacity (~1–3 W/cm²) |

| √ Lower cost | × Less effective in compact, enclosed spaces |

| √ No coolant maintenance | × Sensitive to ambient temperature |

| √ Lightweight |

Best Use Cases

- Low to medium power density applications

- E-bikes, scooters, small drones

- Environments with good airflow

Air Cooling Performance Table

| Parameter | Typical Value |

| Max continuous power | < 10–15 kW |

| Heat flux capacity | 1–3 W/cm² |

| Temperature range | 30–90°C |

| Weight penalty | Minimal |

| Maintenance need | Low |

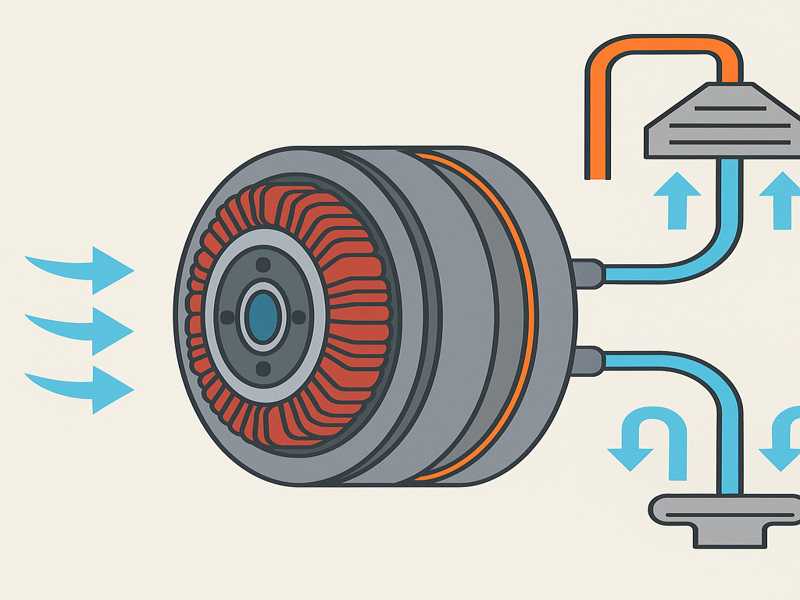

Liquid Cooling: High-Power Thermal Management

How It Works

Liquid cooling involves circulating a fluid—typically water, glycol, or a dielectric fluid—through channels embedded in or around the stator and sometimes the rotor. The liquid absorbs and transfers heat to a heat exchanger or radiator.

There are multiple configurations:

- Stator jacket cooling: Fluid channels around the outer stator

- Embedded channel cooling: Direct liquid contact with copper windings or core

- Immersion cooling: Submerging motor in dielectric fluid

| Pros | Cons |

| √ High cooling efficiency (10–100 W/cm²) |

× Added system complexity and cost |

| √ Compact and modular design |

× Risk of leaks |

| √ Stable operation at high duty cycles |

× Requires coolant pumps and radiators |

Best Use Cases

- High-performance electric vehicles

- Aviation and aerospace

- High-speed industrial robotics

Liquid Cooling Performance

| Parameter | Typical Value |

| Max continuous power | Up to 300 kW |

| Heat flux capacity | 10–100 W/cm² |

| Temperature range | 30–130°C |

| Weight penalty | Moderate |

| Maintenance need | Medium to High |

Advanced Cooling Technologies: Beyond Traditional Systems

As axial flux motors evolve, so too do their cooling needs. Below are next-generation cooling techniques being explored or deployed in prototypes and advanced manufacturing:

Heat Pipes and Vapor Chambers

These use phase-change fluids to rapidly transport heat from the stator to a heat sink.

- Passive system, no pump required

- Excellent for localized hotspots

- Used in aerospace and micro-motor systems

Dielectric Immersion Cooling

Instead of circulating water or glycol, the motor is fully immersed in a non-conductive dielectric fluid (like 3M Novec or mineral oil).

- Direct-contact cooling of stator and rotor

- No short-circuit risk

- High thermal performance

Phase-Change Materials (PCM)

PCMs absorb large amounts of heat during phase transition (solid to liquid), allowing thermal buffering in short high-load bursts.

- Ideal for intermittent-duty cycles

- Common in defense and aerospace

Integrated Cooling Structures

Additive manufacturing (3D printing) enables internal cooling channels within stator laminations or housings, enhancing heat transfer without traditional plumbing.

Comparative Overview: Cooling Methods for Axial Flux Motors

| Cooling Type | Heat Removal Rate | Complexity | Cost | Reliability | Best Fit For |

| Air (natural) | Low (1–2 W/cm²) | Very Low | Low | High | Low-power motors, open systems |

| Air (forced) | Medium (2–5) | Low | Low | High | Consumer e-mobility, low-speed fans |

| Liquid jacket | High (10–50) | Medium | Medium | High | EVs, robotics, compact high-output motors |

| Direct liquid embedding | Very High (up to 100) | High | High | Medium | Aerospace, motorsport, robotics |

| Dielectric immersion | Very High | High | High | Medium | Sealed high-performance applications |

| Vapor chambers/heat pipes | Medium-High | Medium | Medium | Medium | Aerospace, drones, constrained cooling |

| PCM | Low (buffered) | Medium | Medium | Low | Short-duty or burst operation systems |

Design Considerations from a Manufacturer’s Perspective

When designing and manufacturing axial flux motors, the choice of cooling method must be addressed early in the development phase. We focus on the following factors:

Core and Winding Design

Compact stator and rotor assemblies require optimized copper fill factors and lamination stacks that facilitate airflow or coolant contact.

For liquid cooling, grooves or embedded channels must be machined or cast precisely.

Housing and Enclosure

Must accommodate pumps, ports, or fins depending on the cooling system

Die-casting or CNC machining helps shape optimized external heat sinks

Material Selection

Thermal conductivity, corrosion resistance, and dielectric properties all matter

Use of aluminum alloys, high-performance polymers, and coatings

Safety and Testing

Leak tests, thermal cycling validation, and redundant seals are mandatory for liquid cooling

Dielectric immersion systems require full electrical insulation checks

As a custom manufacturer, we offer:

- Custom stator and rotor stack laminations optimized for cooling

- Molded or machined housings with embedded channels

- Full thermal analysis and cooling simulations during the design phase

Real-World Applications and Case Studies

EV Traction Motor with Liquid Cooling

- Motor Power: 150 kW

- Cooling: Embedded liquid jacket

- Outcome: Maintained below 85°C during continuous load, 30% smaller volume than radial equivalent

Drone Propulsion Motor with Forced Air

- Motor Power: 5 kW

- Cooling: Axial fan integrated into rotor hub

- Outcome: Lightweight, simplified system under 4 kg, consistent performance with minor airflow

Industrial Robotic Joint with Immersion Cooling

- Motor Power: 20 kW

- Cooling: Fluorinert-based dielectric immersion

- Outcome: 40% increase in duty cycle; localized peak temp reduced by 18°C

The Future of Axial Flux Motor Cooling

With electrification scaling across all sectors, the need for smarter, more integrated cooling will only increase. Trends include:

- Digital twin simulations for thermal optimization

- Nano-coatings for reducing surface resistance to heat transfer

- AI-controlled liquid pumps that modulate flow based on load

- Compact multi-phase pumps and mini heat exchangers for embedded systems

The industry is moving toward cooling-as-a-system, where motor control, sensor feedback, and dynamic load monitoring help optimize performance in real-time.

Conclusion

Cooling isn’t just an accessory for axial flux motors—it’s an enabler of performance, reliability, and lifespan. Whether using simple air convection or cutting-edge dielectric immersion, choosing the right cooling solution requires balancing performance, cost, complexity, and integration feasibility.

As a manufacturer, we’re committed to delivering axial flux motors and motor cores designed for optimal thermal performance. From prototyping to production, our team collaborates with you to implement the best cooling method for your application.