When it comes to managing water in residential or industrial settings, two types of motors often come into play: Drain Motors and Sump Pump Motors. While both serve the purpose of handling water removal, they are designed to perform distinct roles and operate in different conditions. Understanding their differences is crucial for choosing the right motor for your application, whether it be in a basement, industrial setting, or even in a wastewater treatment facility.

In this article, we will explore the features, differences, and applications of Drain Motors and Sump Pump Motors, with insights on their capabilities, advantages, and potential drawbacks.

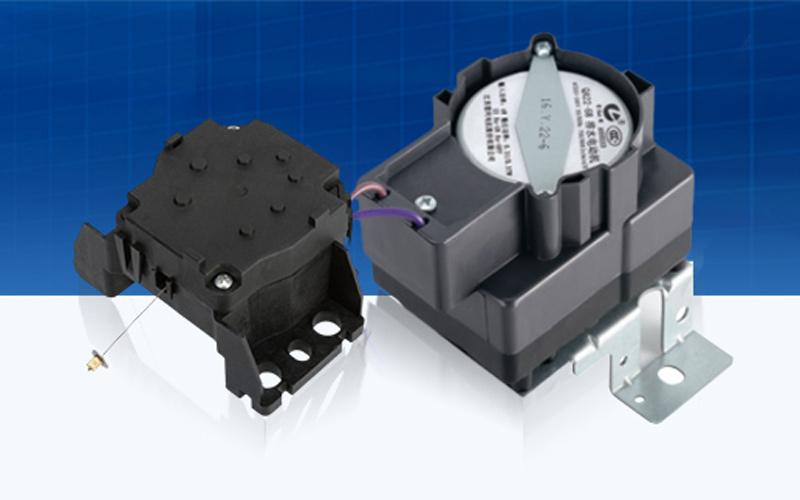

What Are Drain Motors?

Drain Motors are a category of motors used primarily in small-scale water drainage systems. These motors are typically integrated into household or commercial drainage devices to expel water from basements, kitchens, bathrooms, or other areas where water collection is common. Drain motors are commonly seen in systems designed to handle water from appliances like washing machines, dishwashers, and smaller drainage tasks such as handling rainwater runoff.

They can pump water through smaller piping systems, and some models are designed to be mounted inside drainage appliances themselves, such as dishwashers or washing machines.

What Are Sump Pump Motors?

Sump Pump Motors, on the other hand, are specifically designed for pumping water from a sump pit, which is typically located in basements or crawl spaces. The most typical locations for sump pumps are residences and structures that run the danger of flooding or water buildup. The motor within the sump pump drives the mechanism that collects excess water and pumps it away from the building to prevent flooding and damage.

Sump pump motors are larger and more powerful than typical drain motors, as they need to handle large volumes of water. These motors are engineered to run continuously or intermittently, depending on the water level in the sump pit. Sump pumps are usually installed in systems where they work autonomously, powered by float switches that detect the water level.

How Do Drain Motors Work?

Drain motors are designed to efficiently move small amounts of water from one location to another. They often work in conjunction with a pump mechanism to move water away from sinks, bathtubs, dishwashers, and washing machines. The motor is typically activated by a pressure switch or a timer that controls when the motor is running.

A drain motor system’s essential parts are as follows:

- Impeller: A small, rotating device within the pump that pushes the water through the drain system.

- Housing: The outer casing that protects the motor and impeller, often made of durable materials like plastic or stainless steel.

- Seal: To ensure that water does not leak into the motor, high-quality seals are used to protect the motor from water damage.

Drain motors are typically designed for quiet, efficient operation, and many models feature low-power consumption to keep energy costs down.

How Do Sump Pump Motors Work?

Sump pump motors are designed for more heavy-duty use. Usually submerged in a sump pit, they are triggered by a float switch when the water level surpasses a predetermined threshold. Water is drawn from the pit and pumped out of the building, usually via a discharge pipe, using a pump mechanism that is powered by the motor.

The parts of a sump pump system:

- Impeller: Like in drain motors, impellers in sump pumps are used to move water. However, they are usually larger and more durable to handle higher water volumes.

- Float Switch: When the sump pit’s water level is detected, this device activates the motor to begin pumping.

- Pump Housing: This enclosure holds the motor and impeller, often designed to be water-resistant and corrosion-proof for durability in wet environments.

- Discharge Pipe: The water is directed through a discharge pipe that leads outside the building, often far from the foundation to prevent backflow.

Sump pump motors are designed to work under high-pressure conditions and operate for long periods of time without overheating. They often feature thermal protection to prevent damage from running for extended periods.

Applications of Drain Motors

Drain motors are used in various applications requiring the removal of small water volumes. Some common uses include:

- Washing Machines: Drain motors in washing machines expel wastewater after a wash cycle.

- Dishwashers: Drain motors remove used water from dishwashers after cleaning cycles.

- Basin or Sink Drains: In some plumbing setups, a small drain motor is used to remove excess water from a basin or sink.

- Rainwater Collection Systems: Drain motors can also be used in small-scale rainwater harvesting systems to pump collected water.

Applications of Sump Pump Motors

Sump pump motors are used in areas that are prone to flooding or water accumulation. These applications include:

- Basement Flood Prevention: The main functions of sump pumps are to drain basement water, stop flooding, and shield dwellings from water damage.

- Crawl Spaces: Sump pumps are used to keep subterranean spaces dry in dwellings.

- Industrial Settings: Sump pumps are used in factories, warehouses, and plants to remove accumulated water in sumps or tanks.

- Flood Control in Outdoor Areas: Sump pumps are also used in agricultural fields, golf courses, and other outdoor areas where water drainage is necessary.

Key Differences Between Drain Motors and Sump Pump Motors

While both types of motors serve the purpose of water removal, their design, capabilities, and applications differ significantly.

| Feature | Drain Motors | Sump Pump Motors |

| Primary Function | Handles small-scale drainage tasks like appliance drainage. | Pumps large volumes of water from sump pits to prevent flooding. |

| Motor Size | Smaller, compact motors suitable for limited space. | Larger motors capable of handling more substantial water volumes. |

| Power Rating | Generally low-power, typically up to 1/2 HP. | High-power motors, often 1/2 HP to 1 HP or higher. |

| Duty Cycle | Intermittent use in most cases, depending on the appliance. | Continuous or intermittent, depending on water levels. |

| Installation Location | Often integrated into appliances or small drainage systems. | Installed in sump pits, basements. |

| Water Volume Capacity | Low, designed for draining small amounts of water. | High, removes large water volumes. |

| Pumping Height (Head) | Low head height (typically up to 10 feet). | Higher head height (up to 25 feet or more in some cases). |

| Maintenance Requirements | Simple maintenance, typically in appliances or small systems. | Requires periodic maintenance due to heavy usage and longer operational hours. |

| Cost | Typically lower cost due to smaller motor size. | Higher cost due to larger motor and specialized components. |

Real-life Case Studies: Drain Motors and Sump Pump Motors in Action

Case Study 1: Household Drainage System

In a typical household, a drain motor is used in the washing machine and dishwasher systems. The motor is integrated into the water pump system, ensuring that excess water from the appliance is pumped out to the drainage system. These drain motors are compact and have a lifespan of approximately 3-5 years with proper use.

Case Study 2: Basement Flood Prevention

A residential basement in a flood-prone area uses a sump pump motor to manage water overflow from heavy rainfall. The sump pump motor operates intermittently as water fills the sump pit, ensuring the basement remains dry. In such cases, the sump pump motor’s power output plays a crucial role in preventing costly water damage and ensuring the safety of the property.

Conclusion: Which Motor Should You Choose?

The choice between drain motors and sump pump motors depends on the application and the specific needs of the user. If you are dealing with light-duty drainage needs—such as for dishwashers, washing machines, or air conditioners—a drain motor is likely the better and more cost-effective choice.

However, if your goal is to protect your home or business from flooding or manage a high volume of water in larger spaces such as basements or industrial areas, a sump pump motor is more suitable. These motors are specifically designed to handle the high power requirements and continuous operation necessary for large-scale water removal.

In summary, understanding the power requirements, durability needs, and specific applications will guide you in selecting the right motor for your needs, whether it be for household drainage or flood prevention.