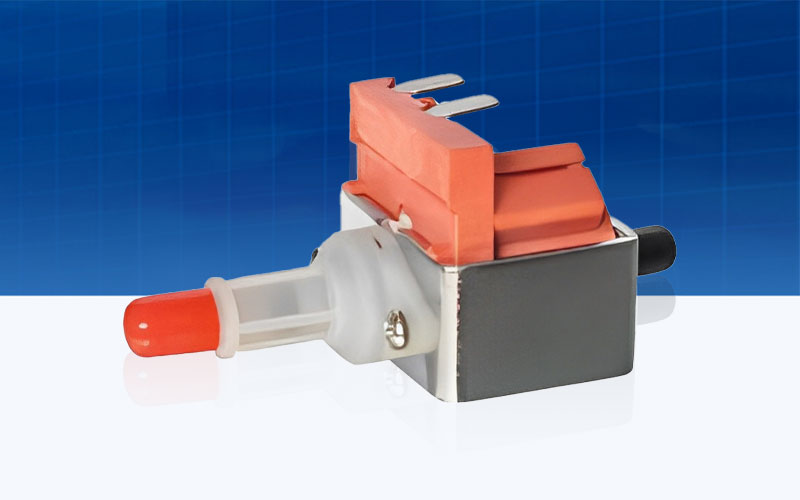

Electromagnetic Pump for Coffee Machine

Our electromagnetic coffee machine pumps use reliable electromagnets and efficient piston technology for leak-free, stable pressure control.

Easy to maintain and energy-efficient, these pumps deliver precision flow, enhancing brewing experience and quality in various coffee appliances.

- Rated Voltage: 120~240 VAC

- Rated Frequency: 50~60 Hz

- Pump Type: Electromagnetic Piston or Diaphragm

- Insulation Class: F

- Wire Material: Copper (Cu)

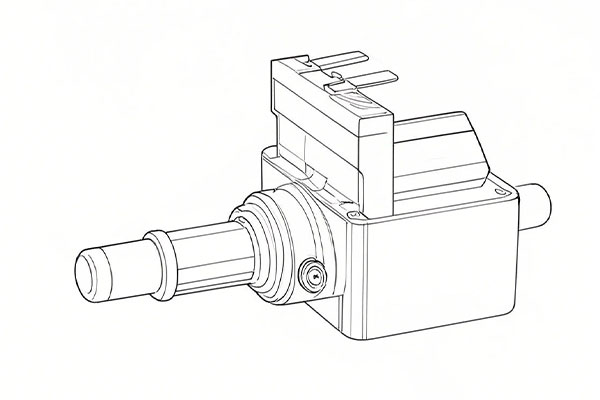

Electromagnetic Pump Component

Coil, piston or diaphragm, valves, spring, chamber, housing, and connector are all parts of an electromagnetic pump that allow for effective fluid flow and control.

- Electromagnetic Coil: Creates magnetic field to actuate piston or diaphragm movement.

- Pump Chamber: Encloses liquid, directing flow through inlet and outlet paths.

- Piston or Diaphragm: Moves fluid by creating suction and discharge actions.

- Spring Mechanism: Restores piston or diaphragm after each movement cycle.

- Inlet Valve: Allows fluid into chamber and blocks reverse flow.

- Outlet Valve: Releases fluid in one direction, preventing return.

- Pump Housing: Encases components and isolates fluid from external conditions.

- Electrical Connector: Supplies power and control signals to the pump.

By Structure

With piston or diaphragm structures, our electromagnetic pumps deliver customized water flow solutions optimized for performance requirements.

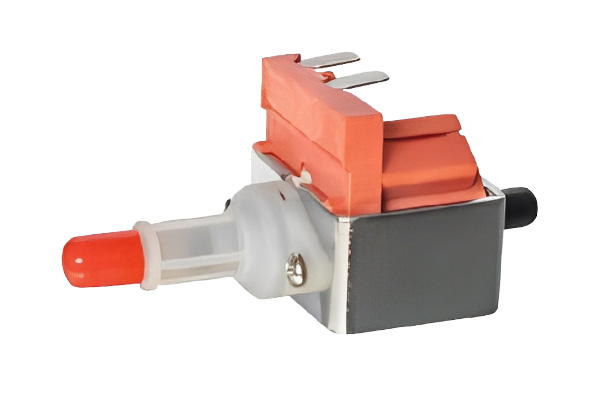

Electromagnetic Piston Pump

- Piston moves water via magnetic force for efficient flow.

- Compact, quiet, durable, and easy to maintain.

- Provides high pressure, ideal for espresso extraction.

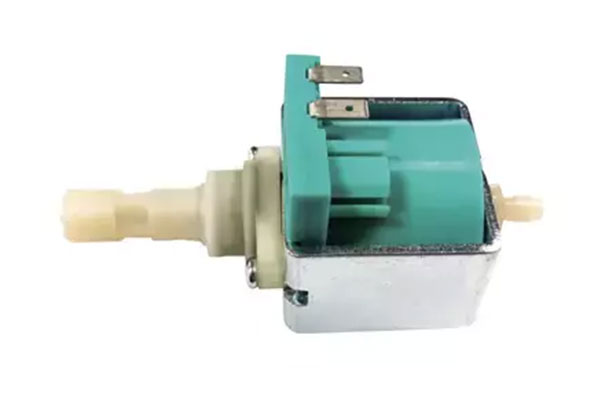

Electromagnetic Diaphragm Pump

- Diaphragm flexes magnetically to displace water smoothly.

- Quiet, energy-saving, compact, and heat-resistant.

- Suited for low-pressure, capsule coffee machine use.

By Control Mode

Two control modes are available for our electromagnetic pumps, allowing for accurate pulse-driven bespoke brewing or steady fixed flow.

Fixed-flow Electromagnetic Pump

- Provides constant flow for stable brewing and pressure.

- Best for repeatable, uniform water delivery systems.

- Affordable for automatic and semi-automatic coffee machines.

Pulse-driven Electromagnetic Pump

- Pulses control flow and brewing pressure precisely.

- Enables programmable flow, pre-infusion, volume control.

- Compact, efficient, suits microcontroller-based systems.

By Motion Type

With the use of quiet linear motion or effective vibratory action, our electromagnetic pumps provide steady pressure and accurate, reliable flow.

Linear Electromagnetic Pump

- Uses linear motion to move piston or diaphragm.

- Quiet, low vibration, compact and durable.

- Stable pressure, precise flow, ideal for espresso.

Vibratory Electromagnetic Pump

- Electromagnetic vibration drives armature or diaphragm.

- Fewer parts, low failure rate, consistent flow.

- Compact, cost-effective, fits capsule coffee machines.

FAQs

1.What are the main components of an Electromagnetic Pump?

Key components include an electromagnetic coil, piston or diaphragm, pump chamber, valves, spring mechanism, electrical connectors, and housing that ensures stable operation and fluid isolation.

2.Can Electromagnetic Pumps handle high temperatures?

Yes, most electromagnetic pumps used in appliances are designed with heat-resistant materials to handle high temperatures safely and reliably during continuous operation.

3.How energy-efficient is an Electromagnetic Pump?

Electromagnetic pumps consume minimal power during operation and maintain high efficiency due to direct magnetic actuation, with little energy lost to heat or friction.

4.Are Electromagnetic Pumps noisy during operation?

No, they are typically very quiet due to minimal mechanical movement and absence of rotating components, making them ideal for indoor and consumer appliance use.

5.Can Electromagnetic Pumps be customized for different appliances?

Yes, manufacturers often customize voltage, flow rate, control mode, size, and housing design to meet specific appliance or industrial application requirements.

6.What is the typical lifespan of an Electromagnetic Pump?

With proper usage and maintenance, electromagnetic pumps can last 5–10 years, depending on operating conditions, fluid type, and frequency of operation.