Professionally Customize Automobile Motor

Recommended Supporting Suppliers for

Global First-tier OEMs

Industrial Product Supporting Capacity

Low Noise,High Quality,Safety, Low Energy Consumption

Industry Innovations

Dishwasher Dispenser Series

- Intelligent tips for a comfortable home life

- Reliable dispensing for the ultimate experience

- Highly adaptable to meet the diverse needs of users

- Modular design for easy operation

New Products for Automotive Air Conditioning Applications

Automotive Air Damper / Motorised Air Vent Actuator

- Miniaturised solutions, Smaller size, Meet the demand for lightweight automotive products

- Domestic chip, Stable supply, Maintain a certain price advantage

- Consistent size and performance, Can replace the imported product programme

Founded in 1993

Stock code 300660

Qualification

Professional customization

Annual production:200 million motors+

500+

World famous brand partner

Products and Applications

-

Home Appliance Market

Committed to providing innovative solutions for the global home appliance industry

- Leading brand in global air conditioning sweep motor market

- A global leader in washing machine drainage systems

- Global Refrigerator lce Water System Solution Provider

Home Appliance Market

Committed to providing innovative solutions for the global home appliance industry

- Customer Cases

- Specific Classfication

Air Conditioner

Air Conditioner Refrigerator

Refrigerator Washing Machine

Washing Machine Kitchen & Bathroom

Kitchen & Bathroom Small Home Appliances

Small Home Appliances

-

Auto Parts

Provide motor and mechatronic components for automobiles

- Product advantages of stepper motors for HUD

- Large-scale automotive water pump production capacity

- Automotive air conditioning system solution capabilities

Auto Parts

Provide motor and mechatronic components for automobiles

- Customer Cases

- Specific Classfication

Air Conditioning System

Air Conditioning System Thermal Management

Thermal Management Intelligent Driving

Intelligent Driving Intake & Exhaust System

Intake & Exhaust System Body Control

Body Control Braking System

Braking System

-

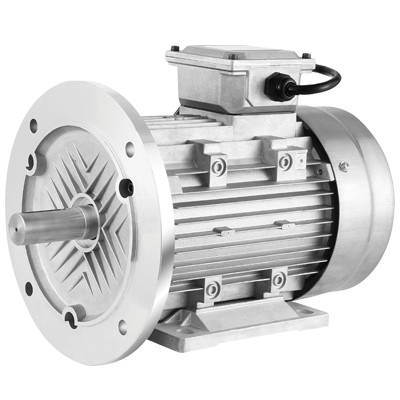

Industrial Control

Provide cost-effective motor and component products in the industrial field

- First-tier brand suppliers in the valve control market

- Domestic security monitoring head enterprise supplier

- Multiple series of products meet different application scenarios

Industrial Control

Provide cost-effective motor and component products in the industrial field

- Customer Cases

- Specific Classfication

Valve Control

Valve Control OA Finances

OA Finances Garden Tools

Garden Tools Industrial Equipment

Industrial Equipment Security Monitoring

Security Monitoring Robot

Robot

-

Sports Health

Provide high-quality motors for sports equipment and medical equipment industries

- High-end sports equipment main drive motor supplier

- First-tier brand suppliers in the medical device industry

- Ability to provide solutions such as smart furniture

Sports Health

Provide high-quality motors for sports equipment and medical equipment industries

- Customer Cases

- Specific Classfication

Sports Equipment

Sports Equipment Medical Instruments

Medical Instruments Game Entertainment

Game Entertainment Smart Home

Smart Home

Outer Diameter 20-50mm

Outer Diameter 6.5-60mm

Outer Diameter 35-60mm

Motors for Valve Control

Full Range of Brushless Types

Various Options Available

DC/AC Programme

Washing Machine Drain Pumps

Automotive Heat Management Pumps

Motors for Valve Control

New Products

- The industrial motor on the market is mainly AC high energy consumption, and the application of permanent magnet motor is less.

Rare Earth Removal Efficient

Permanent Magnet Synchronous Motor

More efficient and energy-saving than same-priced asynchronous motor.

Trending for Industrial Motor Development

- High efficiency, energy saving and green development

- Intelligent and integration

Self-developed Stator Soft Magnetic Material

- Strong plasticity, simple manufacturing process

- Energy saving, environmental protection, high strength

Self-developed Magnetic Rotor Material

- High dimensional stability

- Double permeability design, improve the motor full frequency high efficiency band

Integrated Design

- Small size, light weight

- Intelligent, low noise

- Domestic dishwasher penetration rate is low, the market demand has continued to increase in recent years, the market outlook is large.

Industry Innovative

Intelligent Dishwasher Dispenser

Multiple options for different types of detergents.

Dishwasher Development Trend

- High-end functional requirements

- Wider market prospects for embedded / single-use

- Dishwasher detergents towards integration and liquidisation

Highly Adaptable

- Four options to choose from

- Meets most of the dishwasher detergent dispensing needs on the market

Reliable Detergent Dispensing

- Reliable, active pushing out of the dishwasher block

- Liquid filling pump with good liquid viscosity adaptability

Modular Design

- Modular design, simple structure

- Plug-in installation of the dosing pump

- Increasing demand for automotive comfort, automotive air conditioning market trends towards electrification and intelligence.

Automotive Air Damper / Motorised Air Vent Actuator

Miniaturised solutions for lightweight requirements.

Automotive Air Conditioning Air Vents Market Trends

- Automotive air conditioning air vents electrification, intelligence

- Large air outlet area, wide-angle wind sweeping

- Require high efficiency and good stability of air vents

Product Lightweighting

- Miniaturised solutions with smaller dimensions

- Meet the demand for lightweight automotive products

Stable Supply

- Domestic chip, can provide stable supply

- Maintain a certain price advantage

Substitute for Imported Products

- Maintain the same size and performance

- There can be a substitute for imported products programme

Client Cooperation

Providing you with a full range of CUSTOMISED SERVICES

Relying on the application advantages and customer base in the drainage system of washing machines, Leili continues to meet the needs of new projects of customers and provide customized solutions for the functional requirements of high-end washing machines. After years of research and development, the automatic feeding system for washing machines has been mass-produced by customers such as Little Swan and Whirlpool.

The application of Leili motor in refrigerator products is mainly synchronous motor. In recent years, the customer’s demand for refrigerator ice-making function, Leili motor and the customer close communication, collaborative research and development of refrigerator ice and water system components, for the customer to produce high-end refrigerator to provide assistance. At present, the refrigerator component products have been developed in series for different application scenarios of different customers such as Whirlpool, Midea and GE.

News Center

LEILI is excited to participate in the upcoming 137th Canton Fair, scheduled from April 15th to April 19th at the Canton Fair Complex, No.382, Yuejiang Zhong Road, Guangzhou. As a global leader in motion control and motor solutions, LEILI is excited to meet customers, partners, and visitors from around the world during this premier international trade event.

This spring session of the Canton Fair, known as China’s largest and most comprehensive trade fair, presents an invaluable opportunity for industry professionals to explore the latest trends, forge new connections, and discover cutting-edge products. At LEILI, we are proud to be part of this dynamic platform once again.

Visit LEILI at Booth No. 19.2E35-36, 19.2F13-14

We warmly welcome all attendees to visit us at our booth No. 19.2E35-36 and 19.2F13-14, where we will showcase our full portfolio of innovative motor products and intelligent drive systems. From precision micro motors to integrated motion control solutions, LEILI’s products are widely applied in smart home appliances, medical equipment, industrial automation, and automotive systems.

Visitors will have the chance to:

- Examine the introduction of new products with cutting-edge features and increased effectiveness.

- Experience live demonstrations of our motor solutions in action

- Engage with our professional team to discuss custom solutions for your application needs

- Discover LEILI’s latest R&D advancements in brushless motors, stepper motors, servo systems, and more

With over two decades of expertise and a strong commitment to innovation, LEILI continues to lead the way in delivering reliable, energy-efficient, and intelligent motor solutions to clients around the globe.

What to Expect at LEILI’s Booth

Our booth will highlight LEILI’s core technologies and product advantages. You’ll see:

- High-performance BLDC motors designed for smooth operation and high torque output

- Stepper motors and gear motors developed for precise positioning and quiet operation

- Advanced servo drive systems offering superior control for industrial automation

- Customized motor assemblies tailored to meet specific customer requirements

Our engineering and sales teams will be on-site, ready to provide in-depth technical support and one-on-one consultation. Whether you’re seeking a standard model or a fully customized solution, LEILI offers the flexibility and expertise to support your unique project.

Let’s Connect and Innovate Together

The Canton Fair is more than an exhibition — it’s a global meeting point for ideas, technology, and partnerships. At LEILI, we believe in the power of collaboration to create smarter and more sustainable motion solutions. We look forward to sharing our vision and learning from your insights.

Mark your calendar:

📅 Date: April 15–19, 2025

📍 Venue: Canton Fair Complex, No.382 Yuejiang Zhong Road, Guangzhou

🧭 Booth: 19.2E35-36, 19.2F13-14

Welcome to our booth — let’s shape the future of motion together!

A brushless direct current (DC) motor, also known as a synchronous electric motor, is driven by DC electricity instead of a mechanical commutation system. Brushless DC motors have high efficiency and reliability, help lower acoustic noise, and offer dynamic response, high speed range, and long durability, which are among the key features expected to leverage the brushless DC motor market growth.

Request For Sample Copy of this Research Report:https://www.coherentmarketinsights.com/insight/request-sample/1438

The higher efficiency of brushless DC motors in comparison with other induction or magnetic motors is driving the growth of the brushless DC motors market. Brushless DC motors are more efficient than their brushed DC counterparts, as it is associated with lower mechanical wear outs, thus lowering maintenance costs.

Brushless motor operates at low temperatures, require minimum maintenance, are thermally resistant, and remove any threat of sparks. This, in turn, has increased the demand for brushless motors over other types. Integration of sensor-less controls in brushless DC motors helps boost the durability and reliability of the product, in turn decreases the number of mechanical misalignment and electrical connections and reduces the weight and size of the product. The demand for the sensor-less controls from the industrial machinery has increased considerably due to its low cost and robust motor drives.

Among end users, the industrial automation equipment segment held the largest market share in the brushless DC motors market due to the growing demand for hybrid and electric cars. According to the International Energy Agency, in 2016, electric car sales were over 750 thousand worldwide. The consumer goods segment is rapidly growing due to increasing demand for heating, ventilation, and air conditioning (HVAC) technology, which in turn is increasing the demand for brushless DC motors.

Asia Pacific held the large brushless DC motors market share due to the rising production of electric cars and increasing demand for consumer electronics. According to the International Energy Agency, in 2016, China held the largest market share in the electric cars market, accounting for over 40% of the global electric cars sold.

The market in North America is expected to witness the fastest growth due to the growing demand for extremely sophisticated medical devices. For example, the development of positive airway pressure (PAP) breathing apparatus for the treatment of sleep apnea. This device, which helps patients in breathing also employs a brushless DC motor to power the blower fan.

Key players operating in the brushless DC motors market include Johnson Electric, Ametek, MinebeaMitsumi Inc., Allied Motion Technologies Inc., Maxon Motor AG, Emerson Electric Corporation, ABB, Nidec Corporation, and ARC Systems.

For More Information: https://www.coherentmarketinsights.com/ongoing-insight/brushless-dc-motors-market-1438

Another year of glorious blossoms in spring and solid fruits in autumn, let us forge ahead and open a new chapter. On November 26, 2024, the signing ceremony of the cooperation agreement “Research and Development of Six-Phase Brushless Motor and Controller with Torque Feedback” between Changzhou Leili Motor Technology Co., Ltd., a subsidiary of Jiangsu Leili, and Southeast University was successfully held at Motor Technology. Liu Xiaoyu, chairman of the Science and Technology Association of Changzhou Xinbei District and member of the Party Group of the District Science and Technology Office; Huang Yunkai, member of the Party Committee and deputy dean of the College of Electrical Engineering of Southeast University; and Jiang Zheng, deputy director of Longhutang Street of the district, attended the event.

At the ceremony, Su Da, Director General of Engine Technology, welcomed and thanked the visitors and stated that the signing of this industry-university research cooperation agreement marks a milestone in the more than 10 years of cooperation between the two sides, which will further boost cooperation. Engine Technology will continue to adhere to the principles of open cooperation and mutual benefit, and will explore new solutions and models with Southeast University in talent development, scientific research, and the transformation of achievements, jointly exploring the development of cutting-edge fields.

Huang Yunkai, Vice President of the College of Electrical Engineering at Southeast University, introduced the cooperation project and the university’s current research direction and held in-depth discussions with Mr. Su and the technical team. Liu Xiaoyu, President of the District Science and Technology Association, praised the cooperation between the College of Electrical Engineering and Southeast University. He noted that the government will provide policy support and guidance, and expressed his hope that the three parties—the college, the district, and the enterprise—will cooperate and promote technological innovation to a higher level. After the ceremony, Mr. Su led a delegation of guests to visit the company’s exhibition hall, introducing the company’s mature and outstanding products one by one and sharing future development plans.

We firmly believe that through close collaboration and collaborative efforts between schools and businesses, they can quickly meet the operational needs of intelligent driving in the new energy market and promote the development of new-level productivity. At the same time, both sides will actively explore new models of deep integration between industry, academia, and research, seeking to share resources and gain complementary advantages by cultivating high-quality innovative talent and creating high-level scientific research platforms, thereby boosting the competitiveness and social influence of enterprises.

Efficient airflow management is a cornerstone in industrial applications, HVAC systems, cleanrooms, data centers, and many other engineered environments. The fan market has evolved tremendously over the years, with more sophisticated solutions delivering higher performance, lower energy consumption, and superior control. Among the most significant advancements are Electronically Commutated (EC) backward-curved centrifugal fans—often touted as the new benchmark in airflow technology.

In contrast to traditional fan types—such as axial fans, forward-curved centrifugal fans, and standard induction-motor-driven backward-curved fans—EC backward-curved centrifugal fans provide several advantages. However, understanding where these advantages apply most, and when traditional fans still serve effectively, is crucial for designers, engineers, and procurement specialists.

Fan Technology Overview

Before diving into direct comparisons, it’s useful to summarize the technologies under discussion.

Electronically Commutated (EC) Backward-Curved Centrifugal Fans

EC fans use a brushless DC motor with integrated electronics that combine the motor and variable speed drive into one compact assembly. The impeller in a backward curved configuration has blades that curve against the direction of wheel rotation.

Key characteristics:

- Combines motor and drive electronics in one unit

- Delivers high efficiency across various operating conditions

- Minimizes electrical losses for enhanced performance

- Offers precise control with variable speed capabilities

- Low noise compared to conventional motors

Traditional Fan Types

Traditional fans can be grouped into a few broad categories:

- Axial Fans – Air moves parallel to the axis, offering simplicity and cost-effectiveness, but limited pressure.

- Forward-Curved Centrifugal Fans – Impeller blades curve with rotation, making them ideal for low-pressure systems, such as HVAC.

- Backward-Curved Centrifugal Fans (Standard) – Blades curve against rotation, higher pressure capability, often driven by AC induction motors.

- Propeller Fans – A subtype of axial fan for low-pressure, high-volume applications (e.g., ventilation).

- Tubeaxial and Vaneaxial Fans – Axial fans with duct adapters for HVAC air movement.

Fundamental Performance and Efficiency Comparison

Performance and efficiency are critical when selecting a fan. They determine energy consumption, space requirements, and utility cost over the lifecycle.

Aerodynamic Performance

Backward-curved centrifugal fans generate higher static pressures, making them ideal for ducted systems with significant airflow resistance.

Below provides a concise comparison of various fan types in terms of static pressure capability, airflow range, and typical applications.

Performance Comparison of Fan Types

| Feature / Metric | EC Backward Curved Centrifugal | Standard Backward Curved Centrifugal | Forward Curved Centrifugal | Axial / Propeller Fans |

| Static Pressure Capability | High | High | Moderate | Low |

| Airflow Range | Moderate to High | Moderate to High | Moderate | High |

| Efficiency | Very High | Moderate | Low to Moderate | Moderate |

| Energy Control / Variable Speed | Excellent (integrated) | Good (external VFD) | Fair | Good (external VFD) |

| Noise Levels | Low | Moderate | Moderate to High | High |

| Typical Applications | HVAC, Data Centers, Cleanrooms, Industrial | HVAC, Industrial | HVAC, Low-Pressure Duct Systems | Ventilation, Cooling |

| Cost | Higher upfront | Moderate | Lower | Lowest |

Efficiency and Energy Use

EC backward-curved fans utilize permanent magnets and integrated drive electronics which greatly reduce electrical losses common in induction motors. This translates to up to 50%+ savings in energy use compared to traditional AC motor fans in variable load applications.

Traditional fans typically use AC induction motors. When paired with Variable Frequency Drives (VFDs), they can achieve some level of speed control but still suffer from additional conversion losses and control limitations.

System Control and Integration

One of the key advantages of EC fans is their integrated control logic, which is designed to seamlessly connect with:

- Analog signals (0-10V, 4-20mA)

- Digital communication (Modbus, BACnet)

- Feedback sensors (pressure, temperature, humidity)

This capability enables:

- Airflow optimization based on real-time demand

- Reduced energy waste during off-peak conditions

- Integration with building automation systems

By contrast, traditional fans require external drives and controllers to achieve similar control, increasing complexity and installation costs.

Durability, Maintenance, and Lifecycle Considerations

A fan’s total cost of ownership is heavily influenced by its reliability and maintenance needs.

Motor Durability

- EC Fans: Use brushless motors with electronic commutation. Less mechanical wear, lower heat generation, and typically longer life if operated within rated conditions.

- AC Induction Motor Fans: Simple and rugged but constitute wear in bearings and belts (if present). They often require periodic inspections and maintenance.

Bearing and Impeller Wear

Backward-curved centrifugal fans generally produce less turbulence at the inlet and discharge, reducing mechanical stress and extending operational life.

Maintenance Needs and Downtime

Maintenance activities like lubrication, belt replacement, and drive servicing are more frequent with traditional fan assemblies, especially in demanding environments.

EC fans simplify maintenance schedules due to fewer wearable components and integrated diagnostics that can alert operators to service needs.

Cost Analysis: Upfront vs. Lifecycle

Upfront Costs

- EC Backward-Curved Fans: Higher upfront cost due to integrated electronics and advanced motor technology.

- Traditional Fans: Lower initial cost, especially simple axial or forward-curved fans.

However, upfront costs do not reflect true value.

Operating Costs

EC fans run more efficiently and adaptively, resulting in:

- Lower electricity bills

- Reduced HVAC loads

- Lower peak demand charges

- Extended system life

For facilities operating multiple fans continuously (e.g., data centers, commercial HVAC), energy savings often pay back the premium on EC fans within 1–3 years.

Lifecycle Cost Comparison

Table 2 below outlines typical cost categories and how EC backward curved fans compare with traditional fans over a 10-year operational life.

Lifecycle Cost Comparison (10-year Estimated)

| Cost Category | EC Backward Curved Fan | Traditional Fan (Induction Motor Driven) |

| Initial Purchase | High | Low to Moderate |

| Installation & Commissioning | Moderate | Moderate |

| Energy Consumption | Lowest | High |

| Control System Costs | Integrated (lower) | External (higher) |

| Maintenance | Low | Moderate to High |

| Downtime & Service Interruptions | Low | Higher |

| Total 10-Year Cost | Competitive / Lower | Higher |

| Return on Investment (ROI) | Good | Moderate |

Noise and Environmental Impact

Noise and vibration are often overlooked factors but critical in comfort-sensitive environments like offices, hospitals, and residential HVAC.

Noise Levels

- EC Backward-Curved Fans: Quieter operation due to smoother motor control and optimized impeller design.

- Traditional Fans: Can generate more noise, especially at higher speeds or under fluctuating loads.

Lower noise also correlates with reduced vibration and structural load, which benefits equipment longevity.

Environmental Considerations

- Energy Efficiency: EC fans reduce energy use and carbon footprint.

- Material Use: EC fans are typically more compact, reducing material consumption.

Recyclability: Many components are recyclable, but electronic modules may complicate end-of-life recycling if not properly managed.

Practical Installation and Application Considerations

HVAC Systems

EC backward-curved centrifugal fans are particularly effective in modern HVAC units because:

- Airflow can be modulated automatically based on demand

- Static pressure compensation is excellent for ducted systems

- Lower sound levels improve occupant comfort

Traditional fans may still be suitable for simple ventilation or applications where control needs are minimal.

Industrial Process Applications

Industrial processes requiring precise airflow, such as drying systems, ovens, and manufacturing lines, benefit from:

- Stable pressure delivery

- Variable airflow control

- High efficiency at partial loads

Data Centers and Cleanrooms

These environments demand reliability and precise control. EC backward-curved fans deliver:

- Consistent airflow under varying thermal loads

- Lower energy draw (critical in high-density compute environments)

- Integration with environmental monitoring systems

- Traditional fans, even high-quality ones, often lag in control and efficiency.

When Traditional Fans Still Make Sense

Despite the advantages of EC backward-curved fans, traditional fans retain relevance in certain contexts.

Low Initial Budget Constraints

Project budgets with tight upfront capital may favor simpler traditional fans where advanced controls are not essential.

Simple Ventilation Needs

Applications focused on basic ventilation (e.g., warehouses, agricultural ventilation) might not benefit significantly from advanced flow control.

Retrofit Scenarios with Minimal Integration Needs

Older systems without modern control infrastructure may not justify the complexity of EC fan installation if the goal is simple replacement rather than system upgrade.

8. Future Trends and Technology Outlook

Fan technology continues evolving. Current trends include:

- Smart IoT integration – fans connected via networks for real-time monitoring

- Predictive maintenance – sensors relay data to anticipate failures

- Advanced materials – composites, coatings to reduce weight and improve performance

- Higher efficiency standards – regulatory push for energy performance (e.g., IE5 equivalents)

EC fan technology aligns well with these trends, making it a future-ready solution compared to traditional counterparts.

Summary and Key Takeaways

EC backward-curved centrifugal fans represent a significant technological step forward in airflow management, combining high efficiency, precise control, low noise, and reduced lifecycle costs. When compared with traditional fan types, especially those driven by AC induction motors, the benefits are particularly notable in:

- Energy efficiency and control

- Lifecycle cost savings

- Integration with automation systems

- Operational flexibility

However, traditional fan types still have roles where simplicity, low initial cost, or basic performance is sufficient.

Conclusion: Choosing the Right Fan Type

Selecting the right fan technology depends on:

- Performance requirements – pressure, airflow, environmental conditions

- Control needs – demand response, automation

- Budget priorities – upfront vs. lifecycle cost

- Noise and comfort considerations

- Integration with existing systems

For most modern commercial and industrial applications, EC backward-curved centrifugal fans offer a compelling combination of performance, efficiency, and control. Traditional fans remain relevant for straightforward, low-pressure ventilation or cost-constrained projects.

A careful evaluation against the criteria above ensures the most effective and economical choice for your airflow system.

In today’s energy-conscious world, efficiency is paramount in every industry, and one of the technologies contributing to this is the EC fan (Electronically Commutated fan). These fans combine the efficiency of direct current (DC) motors with the convenience of alternating current (AC) power sources.

With applications ranging from industrial ventilation to HVAC (Heating, Ventilation, and Air Conditioning) systems, EC fans are rapidly becoming the go-to solution for those looking to reduce energy consumption without compromising performance.

What is an EC Fan?

An EC fan is a type of fan that uses an Electronically Commutated (EC) motor. Unlike traditional AC or DC fans, EC fans feature a brushless permanent magnet motor with integrated electronics that adjust the fan’s speed based on demand. This integration of the motor and controller offers superior energy efficiency and control.

Key Features of EC Fans:

- Energy Efficiency: EC fans are more energy-efficient than traditional fans due to the advanced control of speed and power.

- Quiet Operation: They provide quieter operation by reducing vibration and motor noise.

- Variable Speed Control: EC fans automatically adjust their speed to match the required airflow, optimizing power consumption.

- High Efficiency at Partial Loads: Unlike conventional fans that operate at full power all the time, EC fans use only the energy required for the given load, leading to significant energy savings.

How Do EC Fans Work?

EC fans use a brushless DC motor (BLDC) that combines the best of both AC and DC systems. The key component is the built-in electronic controller that adjusts the speed and power supply. Unlike standard AC motors, which run at a constant speed, EC fans can vary their speed according to the system’s demands, providing a more efficient performance.

The fan operates by:

- Transforming AC power into DC power through an integrated rectifier.

- Controlling the fan’s speed through an integrated electronic controller, which modulates the DC power supply.

- Optimizing airflow by adjusting the motor’s performance based on the load or airflow requirements.

This combination of motor and electronics leads to a closed-loop system that provides improved control over the fan’s performance, ultimately delivering enhanced energy efficiency.

Advantages of EC Fans

Energy Efficiency

A major benefit of EC fans is their energy efficiency, as traditional AC fans run at full speed constantly, regardless of airflow demand. In contrast, EC fans adjust their speed to match the required airflow, ensuring that the motor runs at optimal efficiency.

Variable Speed Control

EC fans feature variable speed control, which allows for dynamic adjustments based on real-time airflow requirements. This flexibility reduces energy consumption during low-demand periods and ensures the fan operates at peak efficiency during high-demand times.

Reduced Operating Costs

By improving efficiency and reducing energy consumption, EC fans help to lower overall operating costs. This is especially useful for applications requiring continuous or prolonged fan operation, like HVAC and cooling systems.

Longer Lifespan

The brushless nature of EC motors eliminates wear and tear associated with traditional brushed motors. This leads to increased durability and reduced maintenance, enhancing reliability and lowering long-term costs.

Quiet Operation

EC fans also offer significantly quieter operation. The fan speed can be controlled more precisely, reducing the noise levels often associated with traditional fans. This is particularly important in environments such as offices, hospitals, and residential buildings, where noise levels need to be minimized.

Environmentally Friendly

EC fans consume less energy, reducing electricity use and lowering greenhouse gas emissions, which helps decrease your operation’s carbon footprint and supports environmental sustainability.

Applications of EC Fans

EC fans are versatile and widely used in various industries including:

HVAC Systems

EC fans optimize airflow, enhance energy efficiency, and boost overall system performance in HVAC applications. These fans can be found in air handling units (AHUs), ventilation systems, and cooling towers, where their energy-efficient operation is critical.

Industrial Ventilation

EC fans are commonly utilized for ventilation in industrial environments. Whether it’s maintaining air quality in factories or providing cooling for equipment, EC fans can ensure that the air volume is controlled efficiently while saving energy.

Data Centers

Data centers need accurate temperature and airflow control to avoid overheating. EC fans vary speed based on heat load, enhancing cooling system performance and energy efficiency.

Refrigeration Systems

In refrigeration, EC fans are used to maintain airflow and temperature control. The variable speed control ensures that the fan operates efficiently, reducing the energy consumed in refrigeration units, which often run continuously.

Appliances

EC fans are increasingly being incorporated into home appliances like air conditioners, heat pumps, and extractor fans, where they provide quieter and more efficient operation compared to traditional fan systems.

Automotive Cooling

EC fans are also used in automotive applications, especially in the cooling systems of electric vehicles (EVs). They regulate battery and motor temperatures, enhancing vehicle performance and longevity.

Types of EC Fans

Axial EC Fans

Axial EC fans move air along the fan’s axis, making them suitable for applications requiring high airflow at low pressure, such as HVAC, ventilation, and industrial cooling.

Centrifugal EC Fans

Centrifugal EC fans generate higher pressure than axial fans and are typically used in systems requiring higher airflow resistance, such as air handling units and ducted ventilation systems.

Backward Curved EC Fans

Backward curved EC fans are designed for high-efficiency applications, providing a good balance between airflow and pressure. They are used in applications where space is limited but high efficiency is required, such as in HVAC systems and ventilation equipment.

Forward Curved EC Fans

Forward curved EC fans offer higher airflow but at lower pressure. These fans are ideal for applications prioritizing air movement over pressure, like small exhaust systems.

Choosing the Right EC Fan

When selecting an EC fan for your application, there are several factors to consider. The right fan will depend on the specific needs of your system, such as airflow volume, pressure, and energy consumption.

Key Factors to Consider:

| Factor | Description |

| Airflow Requirements | Ensure the fan can deliver the required volume of air (CFM or m³/h). |

| System Resistance | Consider the static pressure the fan can overcome, depending on the system’s ductwork. |

| Energy Efficiency | Look for fans with integrated electronics to adjust speed based on load. |

| Noise Levels | Choose fans that offer quieter operation for noise-sensitive environments. |

| Speed Control | Determine if variable speed control is necessary for your application. |

EC fans are a revolutionary step forward in fan technology, offering energy-efficient, reliable, and quiet operation across various industries. By understanding the benefits, applications, and types of EC fans, you can make a more informed decision on which fan is right for your needs, ensuring optimal performance and efficiency.

With their ability to adapt to changing airflow requirements, EC fans are poised to play a key role in future energy-efficient systems. As energy costs rise and environmental concerns grow, adopting EC fan technology is a wise choice for anyone looking to optimize their systems while reducing operational costs.

Permanent Magnet Synchronous Motors are used in EVs, robotics, automation, HVAC, compressors, and high-speed systems for their high efficiency, rapid response, precise control, and compact design.

However, despite their advantages, PMSMs commonly face bearing noise and vibration problems, which directly affect motor performance, lifetime, and user experience.

Why Bearing Noise Matters in PMSM

Bearings are responsible for supporting the rotor, reducing friction, enabling smooth rotation, and maintaining correct alignment. In PMSMs, which often operate at high speeds and require precise rotor positioning for synchronous operation, bearings play a critical role in:

- Rotor stability

- Torque smoothness

- Minimizing friction losses

- Preventing demagnetization from mechanical collisions

- Extending motor lifetime

Any abnormality in bearing behavior — such as noise, vibration, or overheating — leads to:

- Increased energy consumption

- Loss of efficiency

- Reduced accuracy in servo systems

- Higher acoustic noise (unacceptable for EVs and home appliances)

- Premature motor failure

Therefore, diagnosing bearing noise early and implementing corrective solutions is essential for PMSM reliability and performance.

Types of Bearing Noise in PMSM

Bearing noise in PMSM is generally classified into the following categories:

Mechanical Noise

Caused by physical defects or damage inside the bearing:

- Surface wear

- Cracks or pitting

- Cage looseness

- Ball deformation

Mechanical noise usually sounds like:

➡ Grinding, rattling, or knocking

Electromagnetic-Induced Noise

Although bearings are mechanical parts, electromagnetic forces in PMSM can indirectly contribute:

- Magnetic radial forces

- Unbalanced magnetic pull (UMP)

- Cogging torque vibration

This often creates:

➡ Humming, whining, or resonance

Lubrication-Related Noise

Occurs when lubrication is insufficient, contaminated, or broken down:

- Dry rubbing

- Oil starvation

- Grease hardening

Audible symptoms:

➡ Squealing or chirping

Structural Noise

Poor assembly or imbalance in surrounding components:

- Misalignment

- Loose housings

- Incorrect shaft fit

Produces:

➡ Intermittent metal contact sounds

Common Causes of Bearing Noise and Vibration in PMSM

This section provides an engineering-level analysis of factors contributing to PMSM bearing noise.

Overload and Excessive Radial/Axial Force

Bearings experience higher stress when:

- The motor drives heavy loads

- Misalignment increases shaft deflection

- Rotor imbalance produces uneven radial force

- Belt transmissions apply excessive axial load

High radial loads cause premature wear.

High axial loads destroy thrust bearings.

Rotor Imbalance and Unbalanced Magnetic Pull (UMP)

PMSM rotors experience UMP due to:

- Uneven air gap

- Assembly errors

- Magnet tolerance variations

- Rotor eccentricity

UMP pulls the rotor toward one side, increasing bearing stress and causing:

- Vibration

- Audible humming

- Premature bearing fatigue

This is especially common in surface-mounted permanent magnet (SPM) rotors.

Contamination Inside the Bearing

Dust, metallic particles, and moisture create surface abrasion and rust.

Typical contamination sources include:

- Poor sealing

- High-humidity environments

- Manufacturing machining debris

- Aging lubricant breakdown

Contaminated bearings produce an unmistakable rough grinding noise.

Lubrication Failure

Lubrication problems occur due to:

- Grease aging or oxidation

- Excessive temperature

- Over-greasing or under-greasing

- Chemical contamination

High-speed operation beyond grease capability

When lubrication fails, friction increases, leading to:

- Squealing noise

- Sudden temperature rise

- Rapid wear

Misalignment Between Rotor and Stator

Misalignment may result from:

- Incorrect mounting

- Bent shafts

- Poor machining tolerances

- Bearing seat deformation

- Housing warpage under thermal expansion

Misalignment produces:

- Vibration

- Uneven loading on bearings

- Increased acoustic noise

Electrical Current Passing Through Bearings (EDM Damage)

Stray electrical currents may flow through bearings due to:

- Improper grounding

- High-frequency PWM inverters

- Shaft voltage induced by switching radiation

- Poor insulation design

This leads to Electrical Discharge Machining (EDM) pitting on bearing surfaces.

Symptoms:

- Buzzing noise

- Vibration

- Fluting marks on bearings

High-Speed PMSM Rotor Dynamics

High-speed PMSMs (30,000–120,000 rpm) amplify:

- Centrifugal force

- Rotor bending

- Resonance

- Thermal expansion

These factors make bearings sensitive to:

- Imbalance

- Lubricant breakdown

- Incorrect preload

- Noise amplification

Diagnostic Techniques for Bearing Noise and Vibration

Engineers use several quantitative and qualitative diagnostic methods.

Audible Noise Inspection

A simple but effective method.

Operators listen for noises:

- Grinding → mechanical damage

- Whining → electromagnetic excitation

- Chirping → lubrication failure

- Knocking → cage looseness

Often used during routine maintenance.

Vibration Spectrum Analysis (FFT)

Vibration signals are decomposed using Fast Fourier Transform (FFT).

Helps identify:

- Ball pass frequency defects

- Inner/outer race wear

- Cage defects

- Resonance

- Rotor imbalance

FFT is essential for high-speed PMSMs used in EV and robotics.

Temperature Monitoring

Abnormal temperature rise indicates:

- Friction increase

- Lubrication failure

- Overloading

- EDM damage

Thermal imaging cameras or embedded sensors are commonly used.

Shaft Runout Measurement

Measures rotor shaft deviation using:

- Dial indicators

- Laser alignment tools

High runout → bearing preload problems or misalignment.

Acoustic Vibration Sensors (AE Sensors)

Acoustic emission sensors detect micro-fractures inside bearings before failure.

Beneficial for:

- PMSM servo motors

- Robotics

- Medical equipment

Oil/Grease Condition Analysis

Checks:

- Particle contamination

- Moisture content

- Viscosity

Used mainly in industrial motor maintenance.

Symptoms vs Causes of Bearing Noise in PMSM

| Symptom | Likely Cause | Diagnosis Method |

| Grinding noise | Surface wear, contamination | Vibration analysis, disassembly |

| Whining/high-pitch noise | UMP, rotor imbalance, electromagnetic forces | FFT, air gap measurement |

| Squealing | Lubrication failure | Grease test, thermal monitoring |

| Knocking | Cage looseness, misalignment | Shaft runout, visual inspection |

| Buzzing | Electrical discharge (EDM) damage | Shaft voltage test |

| Irregular vibration | Shaft misalignment | Laser alignment |

| Temperature rise | Overload, lubrication failure | Temperature sensors |

Engineering Solutions to Reduce Bearing Noise and Vibration

Solutions fall into several categories: design improvements, operational adjustments, and maintenance practices.

Improve Rotor and Stator Machining Accuracy

Manufacturing tolerances significantly affect PMSM bearing performance.

Actions:

- Reduce rotor eccentricity (<10–20 microns)

- Maintain uniform air gap

- Use precision grinding and CNC machining

- Adopt high-accuracy stamping and stacking for laminations

- Better precision reduces UMP, lowering bearing loads and noise.

Optimize Rotor Balancing

Dynamic balancing is essential for high-speed PMSMs.

Methods:

- ISO G2.5 or G1 balancing grade

- Multi-plane balancing

- Compensation slots

- Magnet weight adjustment

Balance correction significantly reduces vibration amplitude.

Use High-Quality Bearings

Key selection criteria:

- Precision grade: P5, P4, P2

- Material: Chrome steel, stainless steel, hybrid ceramic

- Sealing type: Contact/semi-contact seal

- Cage type: Polyamide for low noise

- Internal clearance: C3, C4 for high-speed PMSM

Hybrid ceramic bearings are preferred for:

- EV motors

- High-speed compressors

- Medical centrifuges

They reduce EDM damage and improve noise performance.

Ensure Proper Lubrication

Solutions:

- High-speed synthetic grease

- Automatic lubrication systems

- Low-temperature grease for HVAC PMSM

- Anti-oxidation additives

In high-speed PMSMs:

- Oil mist lubrication

- Oil-air lubrication system

- are commonly used.

Prevent Electrical Current Through Bearings

To avoid EDM damage:

- Use insulated bearings

- Apply shaft grounding rings

- Improve inverter filtering design

- Increase stator insulation

This prevents bearing pitting and reduces buzzing noises.

Improve Motor Assembly Process

Assembly quality directly affects noise.

Key requirements:

- Correct preload control

- Accurate bearing seat tolerance

- Avoid excessive press-fit force

- Ensure parallelism of bearing housings

- Eliminate shaft burrs

Assembly defects are a major cause of early bearing failure.

Reduce Electromagnetic Vibration Forces

Electromagnetic noise can be reduced by:

- Skewing rotor or stator slots

- Increasing slot number

- Optimize magnet geometry to reduce electromagnetic vibration.

- Minimize harmonic currents for smoother motor operation.

- This solution addresses whining or humming noise.

Structural and Housing Improvements

To avoid resonance or structural amplification:

- Strengthen housing stiffness

- Add damping layers

- Avoid thin-wall housings

Apply finite element analysis (FEA) to predict resonance frequency

Solutions to Common PMSM Bearing Issues

| Bearing Issue | Root Cause | Effective Solution |

| Wear & pitting | Contamination | Improve sealing, clean assembly |

| Squealing | Lubrication failure | Use proper grease, schedule relubrication |

| Buzzing noise | EDM discharge | Use insulated bearings, grounding ring |

| Excessive vibration | Rotor imbalance | Dynamic balancing |

| Overheating | Overload, friction | Reduce load, improve cooling |

| Resonance noise | Weak housing | Structural reinforcement |

| Whining | Electromagnetic forces | Reduce harmonics, optimize rotor/stator design |

Preventive Maintenance Strategies

Proper maintenance ensures long motor life.

Routine Noise & Vibration Monitoring

- Install vibration sensors

- Perform FFT analysis quarterly

- Maintain noise trend records

Scheduled Lubrication

Re-lubrication intervals based on:

- Speed

- Load

- Ambient temperature

Regular Bearing Replacement

Typical PMSM industrial motors replace bearings every:

- 8,000 – 20,000 hours (general)

- 5,000 – 10,000 hours (high-speed)

- 2,000 – 5,000 hours (extreme environment)

Seal Inspection

Replace seals if:

- Cracked

- Hardened

- Oil leakage occurs

Application-Specific Recommendations

EV PMSM Motors

Requirements:

- Low noise

- High speed (up to 18,000 rpm)

- Low friction

Solutions:

- Hybrid ceramic bearings

- Precision balancing

- Noise-optimized rotor skew

Industrial PMSM Motors

Focus on:

- Load capacity

- Easy maintenance

Solutions:

- C3 clearance bearings

- Heavy-duty sealing

- Reinforced housing

Robotics PMSM Motors

Key needs:

- Ultra-low vibration

- Precision positioning

Solutions:

- High-precision P4 or P2 bearings

- Low harmonic windings

- Perfect alignment

Improving PMSM Reliability Requires Engineering + Maintenance

Bearing noise and vibration in Permanent Magnet Synchronous Motors (PMSMs) come from a combination of mechanical, electromagnetic, lubrication, and assembly-related factors. Effective diagnosis requires a combination of:

- Vibration analysis

- Temperature monitoring

- Shaft alignment checks

- Acoustic inspection

- Lubricant condition testing

Meanwhile, long-term solutions include:

- Better rotor balancing

- High-quality bearings

- Improved lubrication systems

- Preventing electrical discharge through bearings

- High-precision manufacturing

- Better assembly processes

By addressing these areas comprehensively, manufacturers and maintenance teams can significantly improve PMSM performance, reduce acoustic noise, extend motor life, and enhance user satisfaction—especially in noise-sensitive industries such as electric vehicles, robotics, and household appliances.

Permanent Magnet Synchronous Motors (PMSMs) have become the preferred choice in electric vehicles, industrial automation, robotics, HVAC systems, servo drives, and high-efficiency compressors. Their high torque density, rapid response, efficiency, and compact build make them ideal today.

Yet, despite excellent performance, overheating remains one of the most common engineering failures in PMSM applications. Unresolved thermal issues lead to irreversible demagnetization, winding insulation degradation, reduced torque production, and complete motor failure.

Why PMSM Overheating Is a Critical Engineering Issue

Because PMSMs rely on permanent magnets (NdFeB, SmCo), their thermal limits are tighter than induction motors. Neodymium magnets rapidly lose magnetization at high temperatures:

- 80–120°C: Start of reversible flux weakening

- 120–200°C: Irreversible partial demagnetization begins

- >200°C: Permanent, severe demagnetization

In addition, other components suffer

- Stator winding insulation weakens at high temperature → short circuits

- Bearings lose lubrication → increased friction and vibration

- Rotor sleeve/retaining ring expands → mechanical failure

- Adhesives used in magnet bonding break down

Overheating therefore directly impacts torque, lifespan, safety, and efficiency.

Where Heat Is Generated Inside the PMSM

Heat in PMSMs originates mainly from:

- Copper losses (I²R) in stator windings

- Core losses (hysteresis and eddy currents) in stator/rotor laminations

- Magnet losses in the rotor (especially at high speed)

- Mechanical losses (bearing & windage losses)

- Switching and conduction losses from the inverter (reflected onto the motor)

PMSMs with high-speed operation, such as EV traction motors or aerospace drives, face extreme rotor heat due to magnet eddy current losses.

Root Causes of PMSM Overheating

Below is a structured table summarizing the most common causes and engineering explanations.

Common Root Causes of PMSM Overheating

| Category | Root Cause | Engineering Explanation |

| Electrical | Excessive current (overload) | Increases copper losses (I²R), heating windings beyond thermal class. |

| Current distortion/harmonics | Additional copper and iron losses due to inverter switching and PWM ripple. | |

| Voltage imbalance | Reduces torque efficiency → higher current draw. | |

| Incorrect d-q current control | Improper Id injection leads to flux weakening or extra stator current. | |

| Magnetic | Magnet eddy current losses | High electrical frequency induces heat inside magnets. |

| Low-grade NdFeB magnets | Lower thermal resistance → faster demagnetization. | |

| Incorrect air-gap design | Excessive flux density → core saturation → hysteresis heating. | |

| Mechanical | Bearing friction | Poor lubrication increases mechanical losses. |

| Rotor eccentricity | Produces unbalanced magnetic pull → vibration + heat. | |

| Thermal | Poor heat dissipation | Insufficient cooling path from winding → stator iron → housing. |

| Inadequate coolant flow / blocked channels | Reduced heat transfer rate. | |

| Hot spots in the winding | Uneven slot fill or poor impregnation. | |

| Manufacturing/Material | High core loss laminations | Low-quality silicon steel increases eddy current heating. |

| Poor slot insulation | Hot spots accelerate insulation breakdown. | |

| Defects in bonding of resin or magnets | Rotor magnets heat unevenly. |

Detailed Analysis of Each Overheating Mechanism

Excessive Copper Loss in Stator Windings

Copper loss Pcu=I2RP_{cu} = I^2 RPcu=I2R is the largest heat source under load.

Causes include:

- Oversized load torque

- Misconfigured motor control (FOC)

- Poor quality copper or insufficient cross-section

- Increased resistance due to high temperature (positive temperature coefficient)

- Harmonics from the inverter

Engineering consequence:

- Temperature rises exponentially with stator current. At 20% overload, temperature can rise by 30–40°C.

Iron Loss (Hysteresis + Eddy Current Loss)

Iron loss increases with electrical frequency and flux density.

- Hysteresis loss → magnetic domains flip each cycle

- Eddy current loss → circulating currents in silicon steel laminations

Root causes:

- High-speed operation (>10,000 rpm)

- Poor lamination quality (thick laminations = higher eddy current)

- Improper magnet design leading to high flux density in the teeth and yoke

For high-speed PMSM (aerospace/EV), iron loss can reach 30–40% of total heat.

Rotor Magnet Heating

Rotor heating is often overlooked but extremely dangerous because magnets cannot dissipate heat as effectively as the stator.

Sources of rotor heating:

- Eddy currents induced in magnets

- High-speed operation creating ripple flux

- PWM switching harmonics

- Unoptimized magnet segmentation

- Magnet sleeve eddy currents (carbon-fiber sleeves solve this)

Excessive rotor heat → irreversible demagnetization.

Demagnetization and Thermal Runaway

When magnets weaken due to temperature:

- Back-EMF decreases

- Current increases to maintain torque

- Higher current increases copper loss

- More heat accelerates demagnetization → thermal runaway

This is one of the fastest failure modes of PMSM.

Control System Errors (FOC Issues)

Field-Oriented Control (FOC) errors can produce excess heat:

- Incorrect Id injection during flux weakening

- Poor torque command tuning

- Unoptimized current loop bandwidth

- High d-q harmonics

- Excessive PWM switching frequency → more iron losses

An unstable controller may push the motor into high current zones unnecessarily.

Mechanical Causes of Heat

Mechanical issues increase friction and mechanical losses:

- Worn bearings

- Misalignment of shaft

- Rotor imbalance

- Contaminated/lost lubrication

- Extra tight seals

Mechanical heating often combines with electrical heating to accelerate failures.

Thermal Path and Heat Dissipation Challenges

PMSMs have a non-uniform thermal path:

- Stator windings cool relatively well due to contact with the housing

- Rotor magnets cool poorly (no direct contact with housing)

- Heat must cross the air gap, which has very low thermal conductivity

- High-speed rotors generate additional air friction

Thus, most rotor overheating results from inadequate thermal escape routes.

Early Warning Signs of PMSM Overheating

Engineers should monitor:

Electrical Symptoms

- Rising stator current

- Drop in back-EMF or torque per ampere

- Higher inverter temperature

- Sudden current oscillations

Mechanical Symptoms

- Vibration or unusual noise

- Bearing temperature rise

- Reduced RPM at same torque

Thermal Symptoms

- Hot spots detected via thermal camera

- Rapid housing temperature increase (>10°C/min)

- Uneven heat distribution across stator slots

Diagnostic Techniques for Overheating PMSM

Temperature Sensors

- PT100 sensors in stator slots

- NTC sensors on the windings

- IR sensors for rotor sleeves

- Thermocouples on end windings

Electrical Diagnostics

- Spectrum analysis of current harmonics

- Back-EMF monitoring

- Thermal drift analysis of resistance (Rθ analysis)

Mechanical Strategies

- Vibration monitoring (accelerometers)

- Bearing health diagnosis

- Air-gap measurement to detect eccentricity

Engineering Fixes: How to Prevent PMSM Overheating

Below are practical engineering solutions used in EV motors, robotics servo motors, industrial drives, and aerospace motors.

Improve Stator Winding Heat Management

- Use high-temperature copper insulation (Class H or F)

- Switch to hairpin or wave winding to reduce resistance

- Increase copper cross-sectional area

- Improve slot-fill factor

- Apply vacuum pressure impregnation (VPI) for better thermal conductivity

- Use thermally conductive epoxy

Reduce Iron Loss and Magnet Heating

- Use higher-grade silicon steel (low-loss NOES)

- Reduce lamination thickness (0.2–0.35 mm for high speed)

- Optimize stator tooth geometry

- Segment magnets (reduces eddy currents)

- Use SmCo magnets for high-temperature applications

- Reduce harmonic flux with optimized PWM

Optimize Control Algorithms

- Tune d-q current loops

- Reduce Id injection during flux weakening

- Adjust switching frequency to reduce iron loss

- Implement Maximum Torque Per Ampere (MTPA) properly

- Apply space vector PWM with harmonic suppression

- Add current limiting logic to avoid overcurrent during acceleration

Improve Cooling Systems

Cooling is the most direct method for reducing overheating.

Cooling Options for PMSM and Their Application Scenarios

| Cooling Method | Description | Usage & Benefits |

| Natural air cooling | Rely on ambient airflow | Small motors, low cost, limited performance |

| Forced air cooling | Fan or blower pushes air across housing | Industrial fans, compressors, servo motors |

| Liquid jacket cooling | Water/glycol flows around stator housing | EV traction motors, high power motors |

| Oil spray cooling | Oil sprayed onto stator/rotor | High-speed, aerospace, racing motors |

| Rotor oil injection cooling | Oil flows through rotor shaft → magnets | Aggressive cooling for EV motors |

| Heat pipes or vapor chambers | Rapid heat transport from hot spots | High-end robotics, aerospace |

| Direct winding cooling | Coolant in hollow copper conductors | Highest efficiency, rare, premium motors |

Mechanical Improvements

- Use ceramic or high-performance bearings

- Reduce rotor eccentricity with precision machining

- Use carbon fiber sleeves for high-speed motors

- Improve lubrication system

- Optimize rotor balancing to reduce friction

Material Upgrades

- High-temperature NdFeB (H-grade, SH, UH)

- SmCo magnets for >200°C environments

- High-strength CF sleeves instead of metal sleeves

- Low-loss 0.2 mm laminations for high-frequency motors

- Thermally conductive potting resin in stator slots

Overheating in High-Speed PMSMs (10,000–60,000 RPM)

High-speed PMSMs face unique thermal problems:

- Rotor mechanical expansion creates friction

- Eddy currents in magnets dramatically increase

- Windage losses grow with speed³

- Even small eccentricities cause major heat

Engineering solutions include:

- Carbon-fiber rotor sleeves

- Segmented magnets

- Skewed stator slots

- Advanced oil-spray cooling

- High-strength SmCo magnets

- 0.1–0.2 mm high-frequency laminations

- Ultra-low harmonic PWM

Case Example: EV Traction Motor Overheating

Typical EV motor overheating symptoms:

- Magnet temperature >160°C

- Stator winding >180°C

- Fast torque drop during hill climbing

- Current overshoot during acceleration

- Decline in driving range (due to efficiency loss)

EV manufacturers use:

- High-speed hairpin winding

- Rotor oil injection cooling

- Carbon fiber retaining sleeves

- High-grade NdFeB (>180°C capability)

- Segmented magnets to prevent eddy currents

- Optimized thermal pathways to housing and coolant jacket

These techniques have reduced EV motor temperature rise by 20–40°C compared with older designs.

Engineering Checklist for Solving PMSM Overheating

Electrical Fixes

- Reduce current

- Tune FOC control

- Use better PWM

Magnetic Fixes

- Improve magnet segmentation

- Use high-grade magnets

- Reduce flux harmonics

Mechanical Fixes

- Improve bearings

- Fix rotor imbalance

Thermal Fixes

- Upgrade cooling system

- Add direct winding cooling

- Use better potting/insulation materials

Material Fixes

- Low-loss laminations

- Carbon fiber sleeves

- High-temperature adhesives

Overheating in Permanent Magnet Synchronous Motors is not caused by a single factor but by a combination of electrical, magnetic, thermal, and mechanical mechanisms. Understanding the heat-generation sources—copper loss, iron loss, magnet eddy currents, mechanical friction, and inverter harmonics—allows engineers to design effective solutions.

By improving control algorithms, optimizing magnet and winding design, upgrading materials, and implementing advanced cooling methods, engineers can significantly extend PMSM lifespan, prevent demagnetization, and improve overall efficiency.

PMSM thermal management is now a critical engineering discipline—especially in EVs, robotics, aerospace, and high-performance industrial drives. Proper engineering ensures stable, safe, and efficient motor performance.