Inrunner Brushless DC Motor

Our inrunner brushless DC motor provides high efficiency, torque, and precision with minimal noise, designed for extreme environments.

It offers exceptional speed, control, and electronic governor compatibility, with various voltage options, and features an intelligent cooling system for reliable performance under vibration.

- Voltage: 6V~310V

- Protection Class: IP 54 (Higher Possible)

- Optional Accessory: Drive

- Customization Options: Size, shaft, motor lead, rated speed, power, etc.

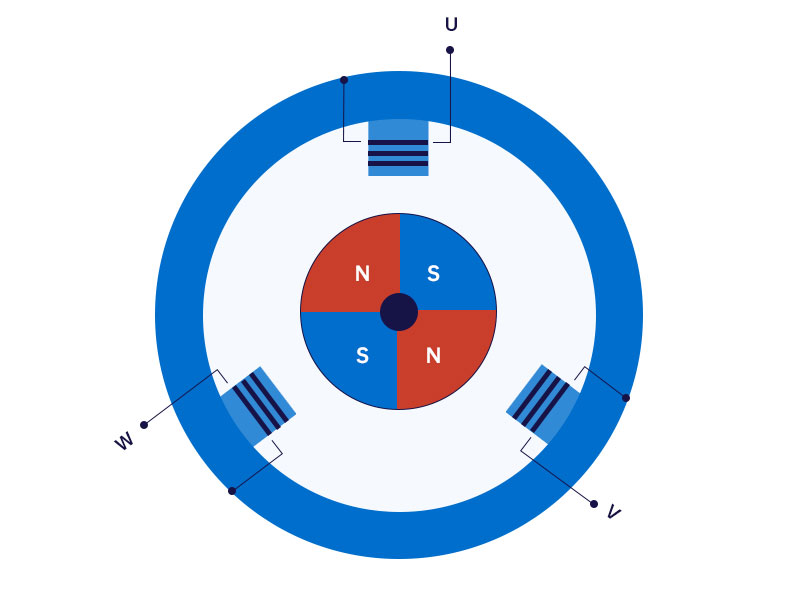

Inrunner Brushless DC Motor Structure

- Our inrunner BLDC motor structure consists of a stator, rotor, output shaft, electronic controller, bearings, and protective housing.

- Stator: Contains windings generating a rotating magnetic field; rotor is placed inside.

- Rotor: Has permanent magnets interacting with stator’s field to produce rotation.

- Electronic Controller: Precisely switches current to control motor speed, direction&torque.

- Output Shaft: Transfers mechanical power from rotor to external load or machine.

- Bearings: Support rotor, allowing smooth rotation and reducing internal friction efficiently.

- Housing/Enclosure: Shields internal motor parts from dust, moisture, and external damage.

Based On Control Method

Trapezoidal, sinusoidal, sensorless, and Hall sensor-based control are several inrunner BLDC motor control techniques that offer varying levels of performance, accuracy, and efficiency.

Trapezoidal Control

- Cost-effective for low to medium-power applications.

- Six steps for smooth, moderate torque operation.

- Suitable for cost-effective, moderate-efficiency applications.

Sinusoidal Control (FOC)

- Smooth, continuous operation with low torque ripple.

- Precise magnetic field control for better efficiency.

- Ideal for high-performance applications requiring precision and smoothness.

Sensorless Control

- No position sensors, reducing complexity and cost.

- Relies on BEMF for rotor position detection.

- Best for low-speed, efficiency-focused applications.

With Hall Sensors

- Uses Hall sensors for accurate rotor position feedback.

- Improves motor control accuracy and smoothness.

- Ideal for precise position control applications.

Based On Size

Compact, conventional, and bespoke sizes are available for inrunner brushless DC motors, which offer specialized power, efficiency, and adaptability for a range of applications.

Compact

- Compact inrunner brushless DC motor, ranging from 10mm to 50mm in diameter, offers high power density and efficiency, ideal for space-constrained applications like portable devices.

Standard

- Standard inrunner brushless DC motor, ranging from 50mm to 120mm in diameter, provides a balance of power, efficiency, and versatility for a variety of industrial and commercial applications.

Customized

- Customized inrunner brushless DC motors, ranging from 10mm to 200mm in diameter, are tailored for applications, offering optimized power, performance, and flexibility for unique or complex systems.

Featured Products

36 Series Inner Rotor Brushless DC Motor

- Voltage: 8-40V

- Rated Speed: 2270~23170RPM

- Current: 0.14~0.64A

42 Series Inner Rotor Brushless DC Motor

- Voltage: 8-26V

- Rated Speed: 2050-7580RPM

- Current: 0.21-0.33A

58WS Inner Rotor Brushless DC Motor

- Voltage: 115~230V

- No-load Power: 1.8~3W

- Load Power: 2.6~4.1W

Applications

Our Inner Rotor BLDC Motors are widely used in fluid systems, healthcare, household appliances, industrial control, material handling, and retail applications, offering precision and reliability.

Fluid & Pumping Systems

- Drive air and water pumps, electric valves, and vacuum systems, ensuring precise fluid regulation and reliable operation for various industrial and automotive applications.

Healthcare Devices

- Power medical rail cars and electric wheelchairs, providing smooth, dependable movement, enhancing mobility and comfort for professionals and improving patient transport efficiency.

Household Appliances

- Used in refrigerators and household devices, offering energy-efficient, long-lasting performance, ensuring smooth operation for cooling, washing, and various household tasks.

Industrial Control

- Essential in automation, driving systems like packaging equipment, ensuring high precision, reliability, and efficiency in manufacturing, production, and industrial packaging operations.

Material Handling Systems

- Used in belt conveyor lines, efficiently transporting materials and goods in warehouses and production facilities, improving workflow and reducing energy use in handling.

Retail & Commercial Systems

- Power conveyor belts in supermarket checkout systems, improving product handling, speeding up checkouts, and enhancing operational productivity in commercial retail environments.

FAQ

1.Can Inrunner Brushless DC Motors operate in extreme environments?

Yes, with protective enclosures, high-grade insulation, and thermal management, they’re designed for high-vibration, high-temperature, or dusty industrial and outdoor conditions.

2.Are Inrunner BLDC Motors waterproof or dustproof?

Yes, motors can be designed with IP-rated enclosures to provide resistance against dust and water ingress in demanding environments.

3.Is maintenance required for Inrunner Brushless DC Motors?

These motors are virtually maintenance-free due to the absence of brushes, requiring only occasional inspection of bearings and electrical connections.

4.Can the Inrunner BLDC Motor be customized for specific applications?

Yes, it can be customized for voltage, speed, torque, mounting style, shaft length, connectors, and thermal requirements, offering application-specific flexibility.

5.Can the Inrunner BLDC Motor be used in medical equipment?

Yes, its low noise, compact form, and precision control make it ideal for ventilators, pumps, and diagnostic devices.

6.What standards apply to Inrunner Brushless DC Motor production?

Depending on the industry, motors may comply with ISO, CE, RoHS, or UL standards for safety, performance, and environmental compliance.