Laser Radar

Product Introduction

- Laser Radar

- Detection Range: Multiple options, 120°FOV, 360°FOV

- Volumetric: Comparatively Small, reducing overall system footprint.

- Accuracy: Up to 300-line equivalent (Luminar Iris), delivering detailed mapping capabilities.

- Warm Reminder:

- The following product parameters are standard products, our company can do product design, development and production according to the special needs of customers. For more information, please contact [email protected]

Product Parameters

I. What is LiDAR

LIDAR is a technological system that uses a combination of lasers, GPS, and inertial measurement units to acquire data and generate highly accurate digital elevation models (DEMs). It is able to accurately measure the position of a light beam hitting a target object and achieve centimeter-level distance measurement accuracy. The biggest advantage of LiDAR is its accuracy and efficient operation ability, which can quickly collect a large amount of data and provide accurate and reliable measurement results for various applications.

2. LiDAR industry prospects

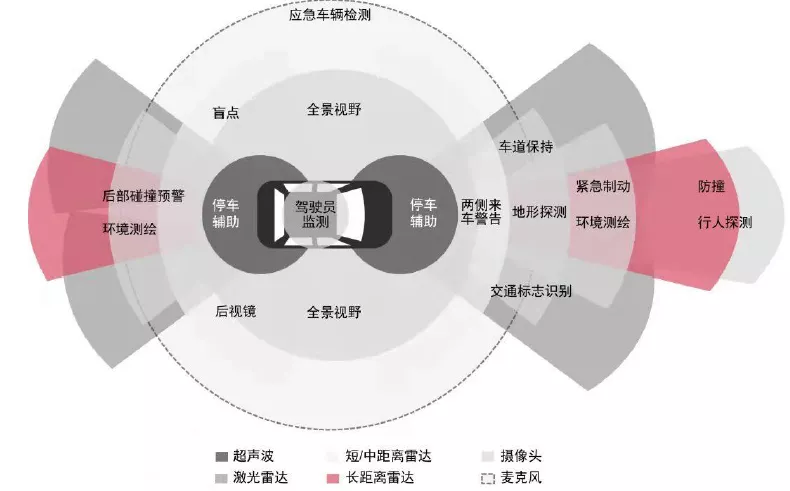

LiDAR, as a core device at the perception level of autonomous driving, has the great advantage of accurate, fast, and efficient operation. Compared with other sensors, such as cameras and millimeter wave radar, LiDAR has become one of the key sensors for autonomous driving above the L3 level. The multi-sensor fusion solution has lower technical barriers and better imaging quality than the pure vision route and is becoming the mainstream path for autonomous driving and advanced assisted driving. Domestic automotive-grade LiDAR standards are gradually improving, and the continuous innovation of semi-solid-state and solid-state technologies further enhances the development potential of LiDAR as a core configuration for autonomous driving.

Mechanical Dimensions: mm

Source: PricewaterhouseCoopers, Anxin Securities Research Center

3. The classification of LiDAR

Mechanical rotation type:

The overall rotation of the transceiver array is driven by the motor to realize the scanning of the horizontal 360° field of view range of the space. The distance measurement capability is consistent within the horizontal 360° field of view.

Semi-solid-state LiDAR:

Semi-solid-state solutions are characterized by the decoupling of the transceiver unit from the scanning components, and the transceiver unit (e.g., laser, detector) is no longer subjected to mechanical movement, specifically including the micro-oscillator solution, rotating mirror solution, etc.. Applicable to achieving part of the field of view angle (e.g., forward) detection, the volume is more compact compared to the mechanical rotating radar.

Solid-state lidar:

Solid-state solutions are characterized by the fact that they no longer contain any mechanical moving parts, including Optical Phased Array (OPA) solutions, Flash solutions, electronic scanning solutions, and so on. They are suitable for detecting part of the field of view (e.g., forward) and are the most compact compared to other architectures because they do not contain mechanical scanning components.

| Mechanical Mean | Semi-solid | Solid State (physics) | ||||

| Rotoscopic | Prismatic | MEMS | OPA | FLASH | ||

| Volumetric | Big | Comparatively Small | Comparatively Small | Small | Minimal | Small |

| Maturity Level | High | High | High | Middle | Lower | Lower |

| Service Life | Short,1000-3000 Hours | High | High | 10,000 to 12,000+ hours | High | High |

| Detection Range | 360°FOV | 120°FOV | 120°FOV | Smaller, requires multiple splices | Smaller, only scans ahead | Smaller, only scans ahead |

| Accurate | Higher, up to 128 lines | Up to 300 line equivalent(LuminarIris) | Equivalent to 144 lines, but point cloud is not uniform and has sparse edges | Higher, can be equated to 160 lines (one diameter tech ML-30s) | High | Relatively Low |

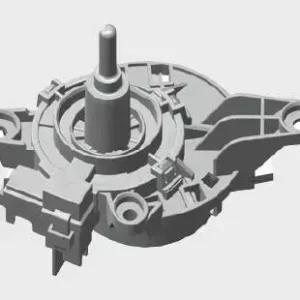

4. LEILI LIDAR motor program.

At present, Leili has two major types of LIDAR motor programs: vibrating mirror and rotating mirror, which can be equipped with two sets of optical encoding and this encoding acquisition system, and can be applied to application scenarios ranging from 300rpm to 10,000rpm. Through the cooperation with the head unicorn enterprises, it has passed the severe environment test of many OEMs and is ranked the first in the world in terms of shipment in the application of high-speed scenarios.

In 2024 rotary mirror and vibrating mirror type motors will account for more than 50% share of the automotive LiDAR industry, and in 2025, we will realize the large-scale mass production of multiple flexible production lines and can meet the demand for multi-species and small batch customization, and continue to provide our customers with products and services with lower cost and higher optical and mechanical reliability.

Leili Motor provides specialized and customized solutions to help customers upgrade their products. Please send an email to [email protected] for additional information.